A Statement About Shale Shaker Screen Made by Kangertong

Kangertong solemnly declares that we only produce the replacement screens but not original ones.

● Derrock, FLC, Hyperpool, PWP, PMD are marks of Derrock Corporation.

● NOV Brandt, VSM, Cobra, King Cobra, D380, D285P and LCM are marks of Varco I/P, Inc.

● M-I SWACO, ALS-2, MD-2, MD-3, MEERKAT PT, MONGOOSE PRO are marks of M-I LLC.

● Scomi, SCM-PrimaG 3P, 4P, 4PDD, 5P are marks of Scomi equipment INC.

● Kemtron 48, Kemtron 28, KTL, KPT are marks of ELGIN separation solutions.

● FSI 5000 series is the mark of Fluid Systems Inc.

* All listed items are right fit replacement shaker screen not originally made by listed famous manufacturer.

* All concerned marks are reserved by the original manufacturer and company.

Interpret API RP 13C in the Form of Question & Answer

1.What is API RP 13C?

1.A new physical testing and labeling procedure for shale shaker screens. To be API RP 13C compliant, a screen must be tested and labeled in accordance with the new recommended practice.

2.Two tests were devised

1.D100 cut point

2.Conductance.

The tests describe a screen without predicting its performance and can be performed anywhere in the world.

1.Once we identify the cut point and conductance complying with API RP 13C, a permanent tag or label should be attached on the visible and legible position of the screen. Both cut point expressed as an API number and conductance shown in kD/mm are required on the screen label.

2.Internationally, API RP 13C is ISO 13501.

3.The new procedure is a revision of the previous API RP 13E.

2.What is D100 cut point meaning?

1.Particle size, expressed in micrometers, determined by plotting the percentage of aluminum oxide sample separated.

2.D100 is a single number determined from a prescribed laboratory procedure – the results of the procedure should yield the same value for any given screen.

3.The D100 should not be compared in any way to the D50 value used in RP13E.

3.What is conductance number meaning?

1.Conductance, permeability per unit thickness of a static (not in motion) shale shaker screen.

2.Measured in kilodarcies per millimeter (kD/mm).

3.Defines a Newtonian fluid’s ability to flow through a unit area of screen in a laminar flow regime under prescribed test conditions.

4.All other factors being equal the screen with the higher conductance number should process more flow.

4.What is API screen number?

1.Number in an API system used to designate the D100 separation range of a mesh screen cloth.

2.Both mesh and mesh count are obsolete terms and have been replaced by the API screen number.

3.The term “mesh” was formerly used to refer to the number of openings (and fraction thereof) per linear inch in a screen, counted in both directions from the center of a wire.

4.The term “mesh count” was formerly used to describe the fineness of a square or rectangular mesh screen cloth, e.g. a mesh count such as 30 × 30 (or, often, 30 mesh) indicates a square mesh, while a designation such as 70 × 30 mesh indicates a rectangular mesh.

5.What does the API screen number tell us?

1.The API Screen Number corresponds to the API defined range of sizes into which the D100 value falls.

6.What does the API Screen Number Not tell us?

1.The API Screen Number is a single number which defines solids separation potential under specific test conditions.

2.It does NOT define how a screen will operate on a shaker in the field as this will depend upon several other parameters such as fluid type & properties, shaker design, operating parameters, ROP, bit type, etc.

7.What is Non-blanked Area?

1.The non-blanked area of a screen describes the net unblocked area in square feet (ft²) or square meters (m²) available to permit the passage of fluid.

8.What is the practical value of RP 13C to the end user?

1.RP 13C provides an unequivocal procedure and benchmark for comparing different screens.

2.The primary intent of RP 13C is to provide a standard measuring system for screens.

9.Should I use the old screen number or the new API Screen Number when ordering replacement screens?

1.Although some companies are changing their part numbers to reflect their conformance to RP 13C, others are not. It is therefore best to specify the RP13C value you want.

|

D100 Separation and API Screen Number |

|

|

D100 Separation (μm) |

API Screen Number |

|

> 3075 to 3675 |

API 6 |

|

> 2580 to 3075 |

API 7 |

|

> 2180 to 2580 |

API 8 |

|

> 1850 to 2180 |

API 10 |

|

> 1550 to 1850 |

API 12 |

|

> 1290 to 1550 |

API 14 |

|

> 1090 to 1290 |

API 16 |

|

> 925 to 1090 |

API 18 |

|

> 780 to 925 |

API 20 |

|

> 655 to 780 |

API 25 |

|

> 550 to 655 |

API 30 |

|

> 462.5 to 550 |

API 35 |

|

> 390 to 462.5 |

API 40 |

|

> 327.5 to 390 |

API 45 |

|

> 275 to 327.5 |

API 50 |

|

> 231 to 275 |

API 60 |

|

> 196 to 231 |

API 70 |

|

> 165 to 196 |

API 80 |

|

> 137.5 to 165 |

API 100 |

|

> 116.5 to 137.5 |

API 120 |

|

> 98.0 to 116.5 |

API 140 |

|

> 82.5 to 98.0 |

API 170 |

|

> 69.0 to 82.5 |

API 200 |

|

> 58 to 69 |

API 230 |

|

> 49 to 58 |

API 270 |

|

> 41.5 to 49 |

API 325 |

|

> 35 to 41.5 |

API 400 |

|

> 28.5 to 35 |

API 450 |

|

> 22.5 to 28.5 |

API 500 |

|

> 18.5 to 22.5 |

API 635 |

D100 Separation and API Screen Number – Select Criteria for Screening

Tell Us Your Request and Get a Free Quote

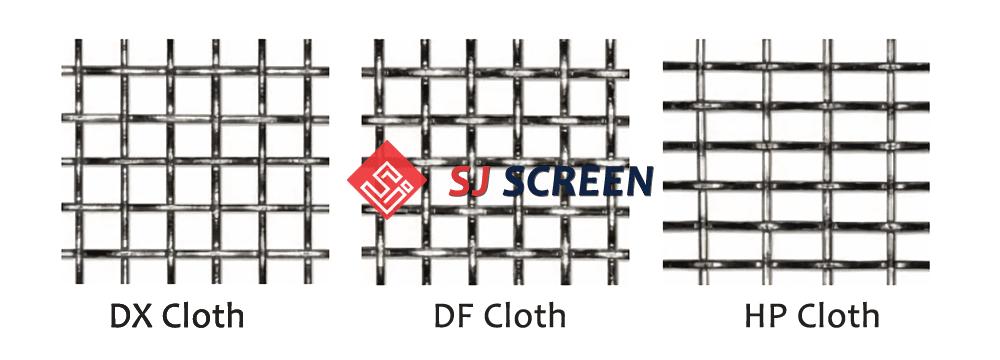

Replacement Shale Shaker Screen Type – DX, DF, HP, XR, XL, MG, HC

(DX™) Cloth

Derrock extra fine cloth series. The DX cloth is designed to maximize capacity, maintain cut point integrity, and minimize near size particle blinding.

(DF™) Cloth

Derrock fine cloth series has a slightly larger wire diameter than the DX cloth, but thinner than market grade and tensile bolting cloth. The DF cloth is designed to maximize screen life, maintain cut point integrity, and minimize nearsize particle blinding.

(HP™) Cloth

Derrock high performance cloth series was developed to increase fluid capacity by utilizing slotted openings. Its slotted openings allow for higher flow rates to be processed without sacrificing cut point integrity.

Remarks:

Derrock, DX, DF, HP are marks of Derrock Corporation.

Kangertong only produces the replacement screens but not original from Derrock.

XR mesh cloth

Rectangular openings and 50%-larger-diameter wire give XR mesh shaker screen mesh excellent capacity and the longest screen life in the industry. High conductance results in reduced mesh loading compared with traditional mesh types.

Ultrafine (XL) screen

The XL screen has been specifically designed for use in drilling sandstone formations, which typically create blinding problems with standard screen mesh types. Our XL mesh features two fine-screening layers with a support mesh having square openings of medium wire diameter for improved capacity, screen life and blinding resistance.

(MG) market grade

MG is featuring a single-layer cloth with heavy wire diameter and square openings. Because of the durable, heavy-wire diameter, the MG is used primarily as a scalping screen with excellent screen life.

HC mesh

Two fine screening layers over a support cloth provide superior performance in blinding applications enable the HC mesh to yield excellent capacity. Screen life is equal to the XL mesh. While the fine wire diameter provides excellent capacity, the HC mesh has shorter screen life and lower separation efficiency compared with our other mesh types.

What factors can influence shaker screen’s performance?

● Screen cut point.

● Screen conductance.

● Screen non-blanked open area.

● Shaker conveyance rate.

● Shaker deck angle.

● Liquid flow rate.

● Liquid phase viscosity.

● Solids sizes.

● Motor vibration.

● Missing rubbers on screen bed.

Post time: Feb-07-2022