Bottom price Derrock FLC313 PWP Screen - Replacement Screen for FLC 2000 48-30 PMD – KANGERTONG

Bottom price Derrock FLC313 PWP Screen - Replacement Screen for FLC 2000 48-30 PMD – KANGERTONG Detail:

Description

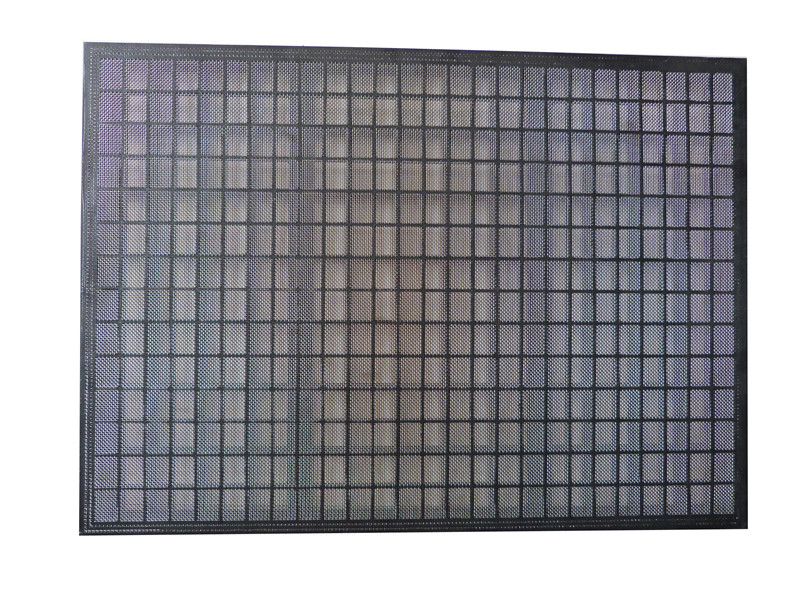

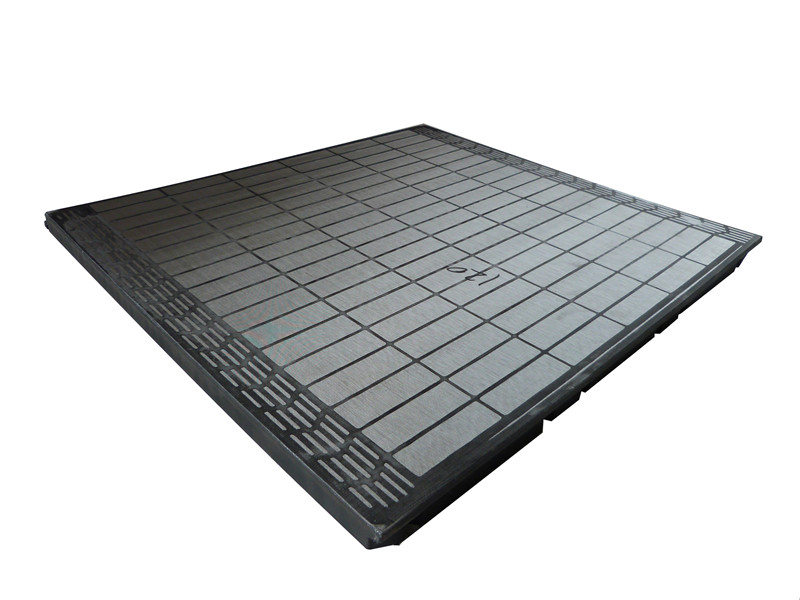

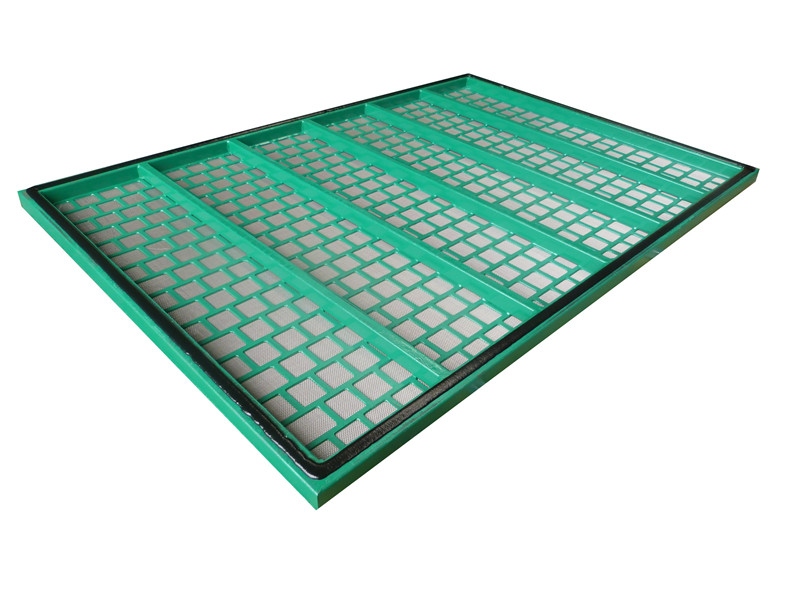

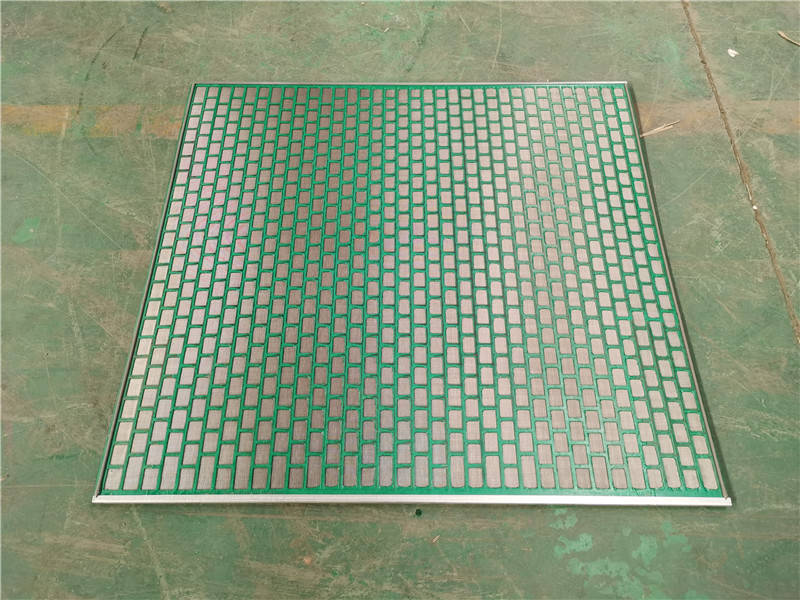

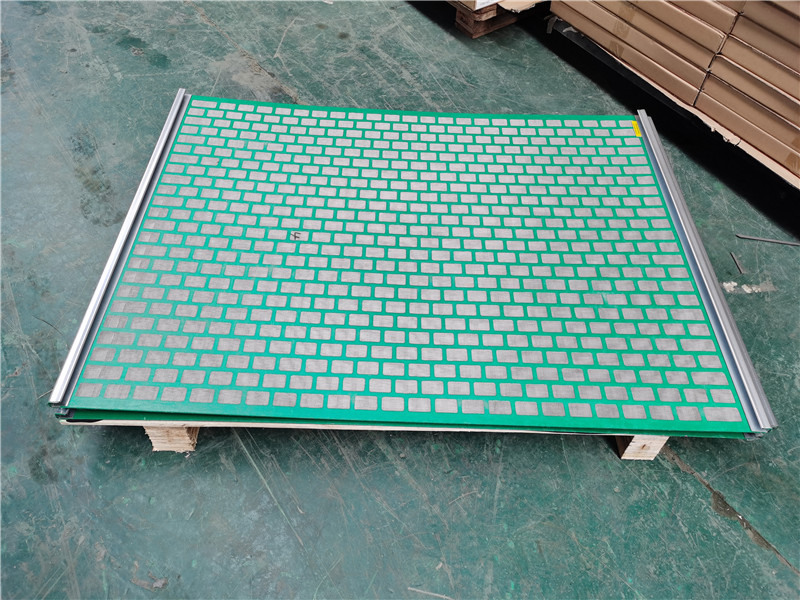

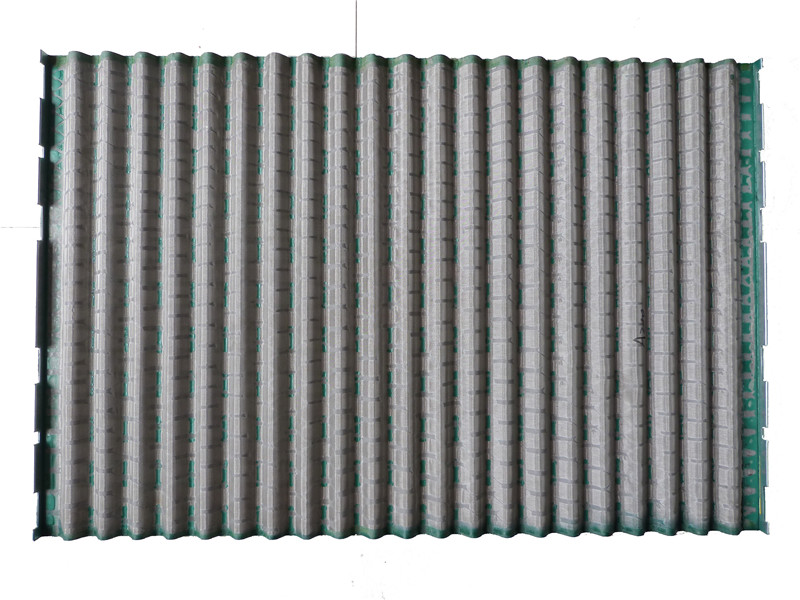

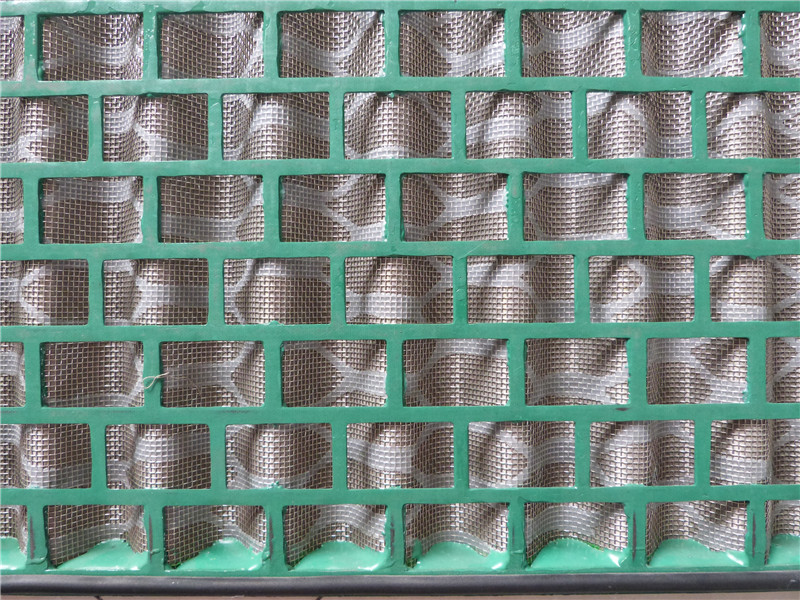

KET-PMD 2000 shale shaker screen is manufactured based on the innovated design of Derrock Corporation. This type of shaker screen is constructed of multiple layers of stainless steel wire mesh cloth with different densities. Arrange these layers reasonably and exactly, the finished shale shaker screen with revolutionary three-dimensional corrugated screens structure. Pyramid screens offer 125% to 150% usable areas of traditional flat multi-layered screens. And the fluid capacity also has been increased.

Adaptable Shale Shaker Model

KET-PMD 2000 shaker screens are used as the substitute screen for

Derrock FLC (Flo-Line Cleaner) 2000 3-panel shaker.

Derrock FLC (Flo-Line Cleaner) 2000 4-panel shaker.

Derrock 48-30 shale shaker.

Derrock FLC (Flo-Line Cleaner) 2000 series mud cleaners.

Derrock FLC Plus, FLC with AWD, HI-G dryer.

Competitive Advantage

API RP 13C (ISO 13501) compliant.

Resistant to corrosion, high temperature and collision.

Larger area and higher conductance.

Increase shaker capacity and reduce mud loss.

Scientific & reasonable cost control system for competitive price.

Higher flow rates without sacrificing cut point integrity.

Adequate inventory in the shortest time to meet customers’ demand.

Warranty Period: 1 year.

Working Life: 400–450 hours.

Performance Parameter

| Screen Designation | Mesh Type | API RP 13C Designation | Conductance Number | D100 Separation (microns) | Layer No. | Non-Blank Area (sq.ft) |

|---|---|---|---|---|---|---|

| KET-PMD 2000-A325 | DF | API 325 | 0.39 | 44 | 2/3 | 8.3 |

| KET-PMD 2000-A270 | DF | API 270 | 0.67 | 57 | 2/3 | 8.3 |

| KET-PMD 2000-A230 | DF | API 230 | 0.71 | 68 | 2/3 | 8.3 |

| KET-PMD 2000-A200 | DX | API 200 | 1.32 | 73 | 2/3 | 8.3 |

| KET-PMD 2000-A170 | DX | API 170 | 1.34 | 83 | 2/3 | 8.3 |

| KET-PMD 2000-A140 | DX | API 140 | 1.89 | 101 | 2/3 | 8.3 |

| KET-PMD 2000-A120 | DX | API 120 | 1.89 | 134 | 2/3 | 8.3 |

| KET-PMD 2000-A100 | DX | API 100 | 2.66 | 164 | 2/3 | 8.3 |

| KET-PMD 2000-A80 | DX | API 80 | 2.76 | 193 | 2/3 | 8.3 |

| KET-PMD 2000-A70 | DX | API 70 | 3.33 | 203 | 2/3 | 8.3 |

| KET-PMD 2000-A60 | DX | API 60 | 4.1. | 268 | 2/3 | 8.3 |

| KET-PMD 2000-A50 | DX | API 50 | 5.17 | 285 | 2/3 | 8.3 |

| KET-PMD 2000-A40 | DX | API 40 | 8.64 | 439 | 2/3 | 8.3 |

| KET-PMD 2000-A35 | DX | API 35 | 9.69 | 538 | 2/3 | 8.3 |

| KET-PMD 2000-A20 | DF | API 20 | 10.88 | 809 | 2/3 | 8.3 |

| * D100: Particles this size and larger will normally be discarded.* API: Corresponding API sieve equivalent as per API RP 13C.* Conductance No.: This represents the ease with which a liquid can flow through the screen. Larger values represent higher volume handing. | ||||||

Product detail pictures:

Related Product Guide:

In an effort to finest meet up with client's requirements, all of our operations are strictly performed in line with our motto High High quality, Competitive Rate, Fast Service for Bottom price Derrock FLC313 PWP Screen - Replacement Screen for FLC 2000 48-30 PMD – KANGERTONG, The product will supply to all over the world, such as: Casablanca, Bulgaria, panama, During the short years, we serve our clients honestly as Quality First, Integrity Prime, Delivery Timely, which has earned us an outstanding reputation and an impressive client care portfolio. Looking forward to working with you Now!

The goods we received and the sample sales staff display to us have the same quality, it is really a creditable manufacturer.