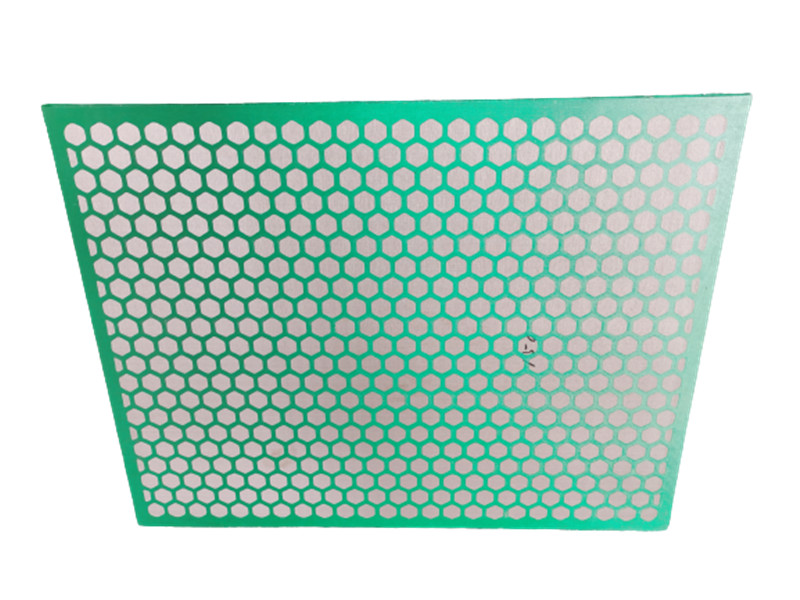

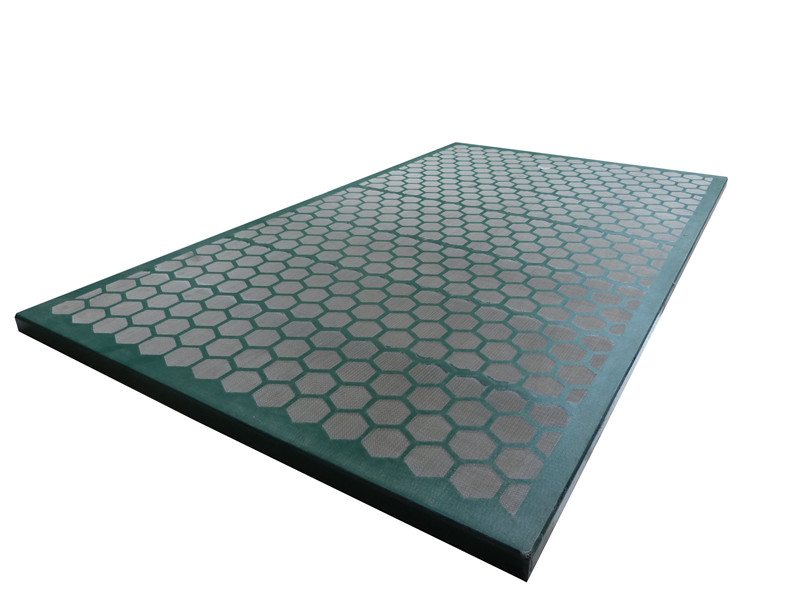

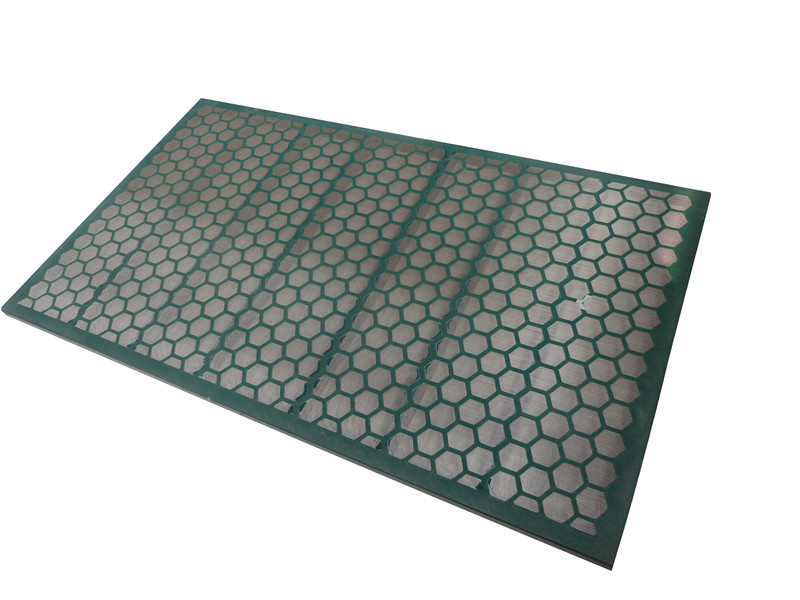

Replacement Screen for Kemtron KPT26 Composite Frame

Technical Parameter

Mesh Material: stainless steel 304/316/316 L.

Frame Material: Q235 steel/PT.

Screen Type: XL, XR.

API RP 13C Designation: API 16 – API 325.

Package: packed in paper carton, shipped by wooden case.

Looking for a reliable replacement for your Kemtron 26 Series Shale Shaker Screen? Look no further than the KET-KPT-26 shaker screens manufactured by ShengJia. These screens are designed to meet API 16 – API 325 specifications, ensuring compatibility with a wide range of applications.

Each KET-KPT-26 screen is constructed with 3 or 4 layers of high-quality 304/316 stainless steel wire mesh cloth, offering excellent durability and longevity. The different layers of mesh cloth are carefully selected to provide optimal separation efficiency, allowing you to achieve the desired cut-point designation.

Rest assured that all KET-KPT-26 shaker screens are API RP 13C compliant, guaranteeing accurate cut-point designation and reliable performance. Upgrade to KET-KPT-26 shaker screens for superior performance and longevity in your operations.

Adaptable Shale Shaker Model

KET-KPT-26 shaker screens are used as the substitute screen for:

KEMTRON KPT 26 shale shaker.

Competitive Advantage

Steel frame and composite frame optional.

100% interchangeable with OEM brands screen panel size.

SS 304/316 wire mesh cloth does not rust or delaminate.

Manufactured according to the API RP 13C (ISO 13501).

Scientific & reasonable cost control system for competitive price.

Adequate inventory in the shortest time to meet customers' demand.

Warranty Period: 1 year.

Working Life: 400-450 hours.

Performance Parameter

| Screen Designation | Mesh Type | API RP 13C Designation | Conductance Number | D100 Separation (microns) | Non-Blank Area (sq.ft) | ||

| XL | XR | XL | XR | ||||

| KET-KPT-26-A325 | XL | API 325 | 0.44 | - | 44 | - | 6.2 |

| KET-KPT-26-A270 | XL/XR | API 270 | 0.38 | 0.48 | 56 | 52 | 6.2 |

| KET-KPT-26-A230 | XL | API 230 | 0.48 | - | 62 | - | 6.2 |

| KET-KPT-26-A200 | XL/XR | API 200 | 0.65 | 0.56 | 81 | 70 | 6.2 |

| KET-KPT-26-A170 | XL/XR | API 170 | 0.85 | 0.89 | 92 | 887 | 6.2 |

| KET-KPT-26-A140 | XL/XR | API 140 | 1.05 | 0.75 | 100 | 104 | 6.2 |

| KET-KPT-26-A120 | XL | API 120 | 1.27 | - | 126 | - | 6.2 |

| KET-KPT-26-A100 | XL/XR | API 100 | 1.34 | 1.6 | 140 | 145 | 6.2 |

| KET-KPT-26-A80 | XL/XR | API 80 | 1.86 | 1.82 | 171 | 173 | 6.2 |

| KET-KPT-26-A70 | XL/XR | API 70 | 2.35 | 2.24 | 219 | 225 | 6.2 |

| KET-KPT-26-A60 | XL/XR | API 60 | 2.95 | 3.37 | 266 | 262 | 6.2 |

| KET-KPT-26-A50 | XL | API 50 | 2.69 | - | 311 | - | 6.2 |

| KET-KPT-26-A35 | XL | API 35 | 7.88 | - | 488 | - | 6.2 |

| KET-KPT-26-A35 | XL | API 35 | 7.88 | - | 488 | - | 6.2 |

| KET-KPT-26-A20 | XL | API 20 | 22.76 | - | 783 | - | 6.2 |

| KET-KPT-26-A16 | XL | API 16 | 34.51 | - | 1146 | - | 6.2 |

| * D100: Particles this size and larger will normally be discarded.* API: Corresponding API sieve equivalent as per API RP 13C.

* Conductance No.: This represents the ease with which a liquid can flow through the screen.Larger values represent higher volume handing. |

|||||||