OEM Manufacturer China Derrock Shale Shaker – Replacement Screen for Derrock 500 – KANGERTONG

OEM Manufacturer China Derrock Shale Shaker – Replacement Screen for Derrock 500 – KANGERTONG Detail:

Description

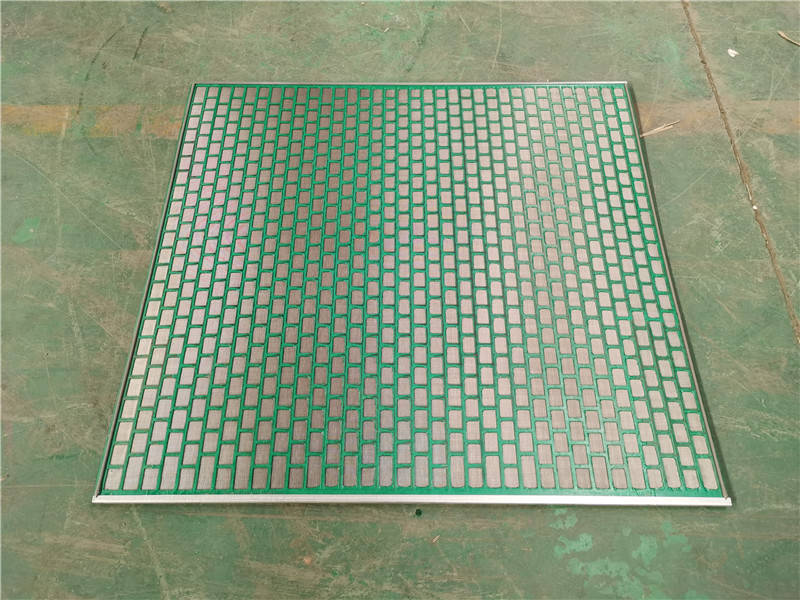

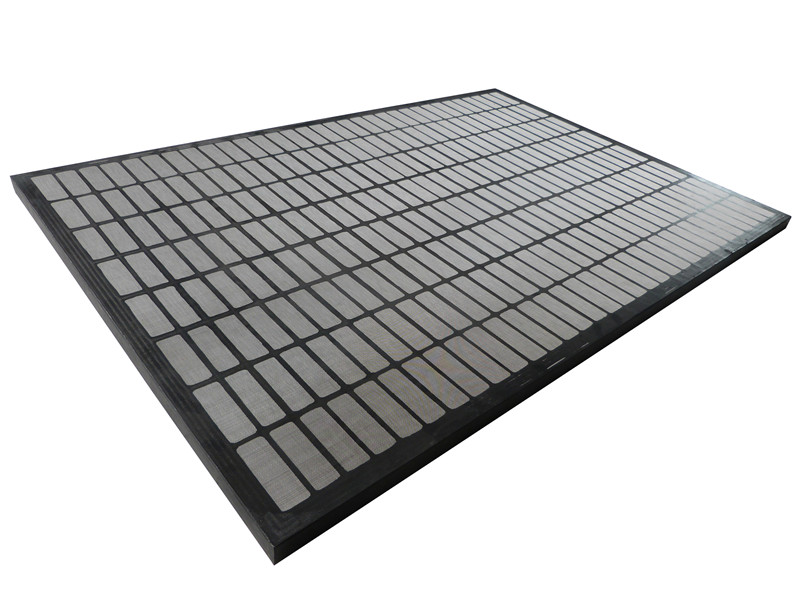

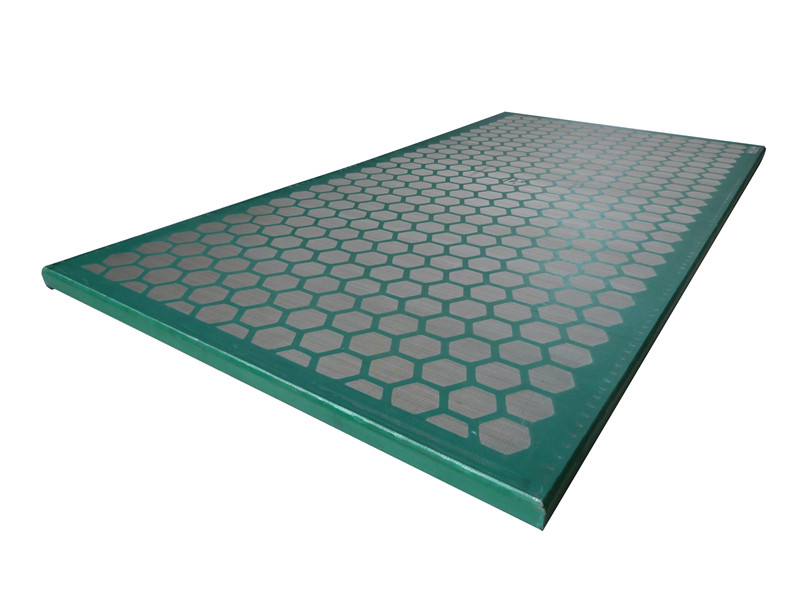

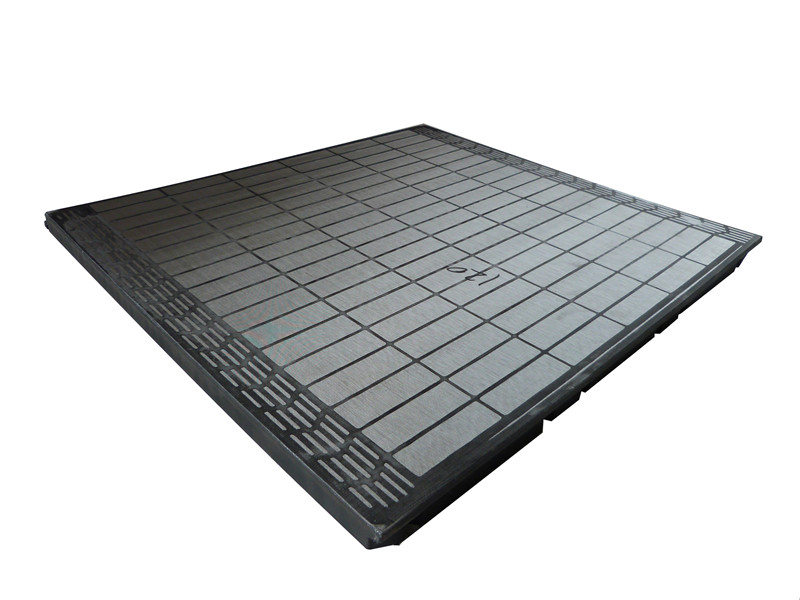

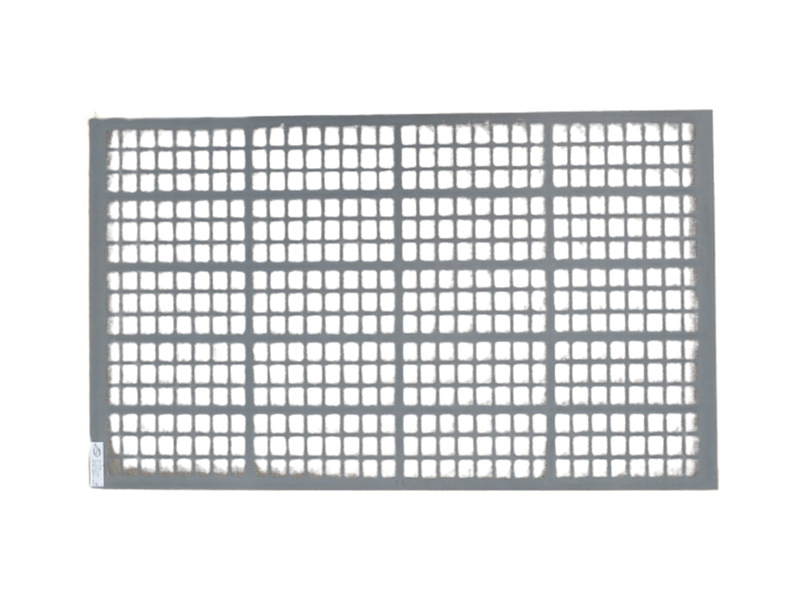

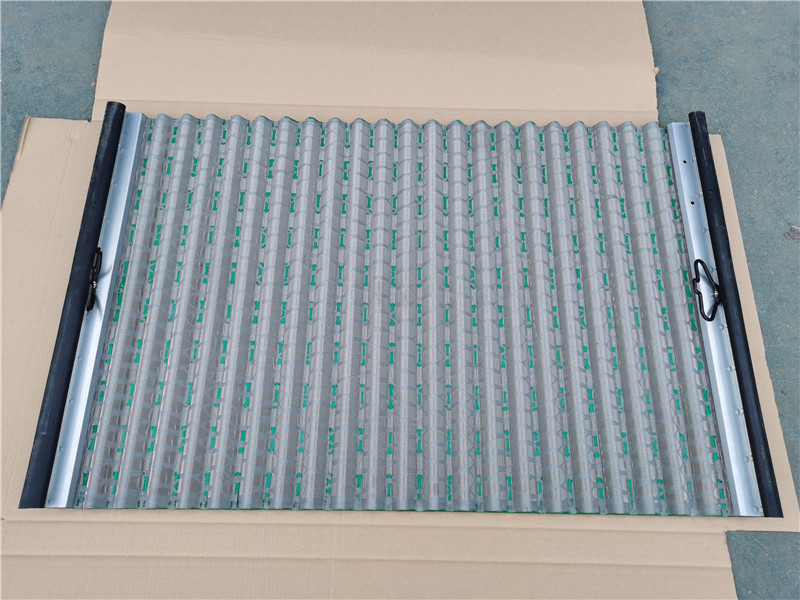

Derrock 500 shaker screen replacement is manufactured for all Derrock 500 series shale shakers. Innovative tension fingers and two quick-lock 1/2 turn tension bolts on each screen panel make the installation faster, easier and more reliable. The bottom layer with low mesh counts is waved by coarse wires, then tightly bonded to the backing plate. It offers longer service life and maximizes the separation efficiency.

Adaptable Shale Shaker Model

KET- 500 shaker screens are used as the substitute screen for

Derrock FLC (Flo-Line Cleaner) 503 shaker.

Derrock FLC (Flo-Line Cleaner) 504 shaker.

Derrock FLC (Flo-Line Cleaner) 503 drying shaker.

Derrock FLC (Flo-Line Cleaner) 504 drying shaker.

Derrock FLC (Flo-Line Cleaner) 513 shaker.

Derrock FLC (Flo-Line Cleaner) 514 shaker.

Derrock FLC (Flo-Line Cleaner) 513 VE (Vapor Extraction).

Derrock FLC (Flo-Line Cleaner) 514 VE (Vapor Extraction).

Competitive Advantage

Resistant to corrosion, high temperature and collision.

Quick-lock tension system, excellent trapping (dreg) effect.

56% more screen surface area than flat screens.

Maximize the solids removal capabilities.

Increase shaker capacity and reduce mud loss.

API RP 13C (ISO 13501) compliant.

Adequate inventory in the shortest time to meet customers’ demand.

Warranty Period: 1 year.

Working Life: 400–450 hours.

Performance Parameter

| Screen Designation | Mesh Type | API RP 13C Designation | Conductance Number | D100 Separation (microns) | Layer No. | Non-Blank Area (sq.ft) |

|---|---|---|---|---|---|---|

| KET- 500-A325 | DF | API 325 | 0.39 | 44 | 2/3 | 7.09 |

| KET- 500-A230 | DF | API 230 | 0.71 | 68 | 2/3 | 7.09 |

| KET- 500-A200 | DX | API 200 | 1.32 | 73 | 2/3 | 7.09 |

| KET- 500-A170 | DX | API 170 | 1.34 | 83 | 2/3 | 7.09 |

| KET- 500-A140 | DX | API 140 | 1.89 | 101 | 2/3 | 7.09 |

| KET- 500-A120 | DX | API 120 | 1.89 | 134 | 2/3 | 7.09 |

| KET- 500-A100 | DX | API 100 | 2.66 | 164 | 2/3 | 7.09 |

| KET- 500-A80 | DX | API 80 | 2.76 | 193 | 2/3 | 7.09 |

| KET- 500-A70 | DX | API 70 | 3.33 | 203 | 2/3 | 7.09 |

| KET- 500-A50 | DX | API 50 | 5.17 | 285 | 2/3 | 7.09 |

| KET- 500-A40 | DX | API 40 | 8.64 | 439 | 2/3 | 7.09 |

| KET- 500-A35 | DX | API 35 | 9.69 | 538 | 2/3 | 7.09 |

| KET- 500-A20 | DF | API 20 | 10.88 | 809 | 2/3 | 7.09 |

| * D100: Particles this size and larger will normally be discarded.* API: Corresponding API sieve equivalent as per API RP 13C.* Conductance No.: This represents the ease with which a liquid can flow through the screen. Larger values represent higher volume handing. | ||||||

Product detail pictures:

Related Product Guide:

The consumer fulfillment is our primary goal. We uphold a consistent level of professionalism, top quality, credibility and service for OEM Manufacturer China Derrock Shale Shaker – Replacement Screen for Derrock 500 – KANGERTONG, The product will supply to all over the world, such as: San Diego, Peru, Adelaide, We have top engineers in these industries and an efficient team in the research. What is more, now we have our own archives mouths and markets in China at low cost. Therefore, we can meet different inquiries from different clients. Remember to find our website to check more information from our merchandise.

The company keeps to the operation concept scientific management, high quality and efficiency primacy, customer supreme, we have always maintained business cooperation. Work with you,we feel easy!