OEM Supply Used Derrock Shale Shaker Screen - Replacement Screen for Derrock 500 PMD – KANGERTONG

OEM Supply Used Derrock Shale Shaker Screen - Replacement Screen for Derrock 500 PMD – KANGERTONG Detail:

Description

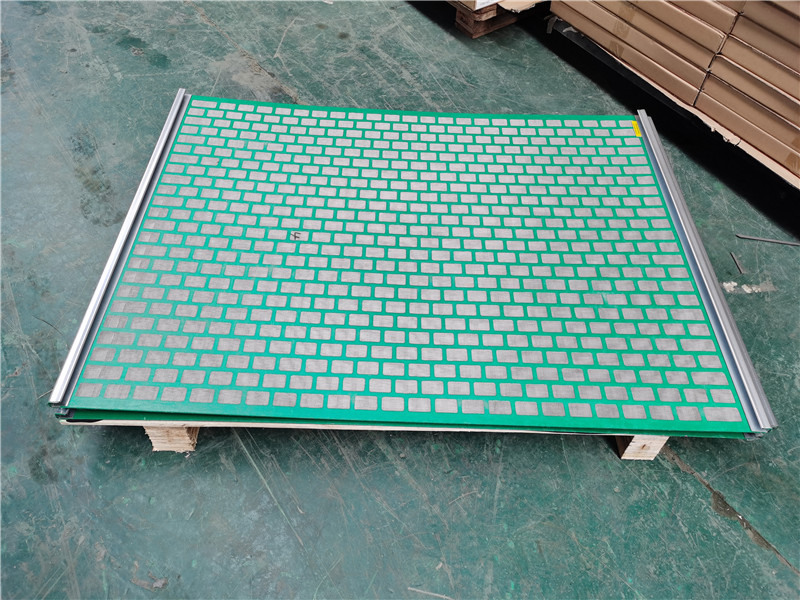

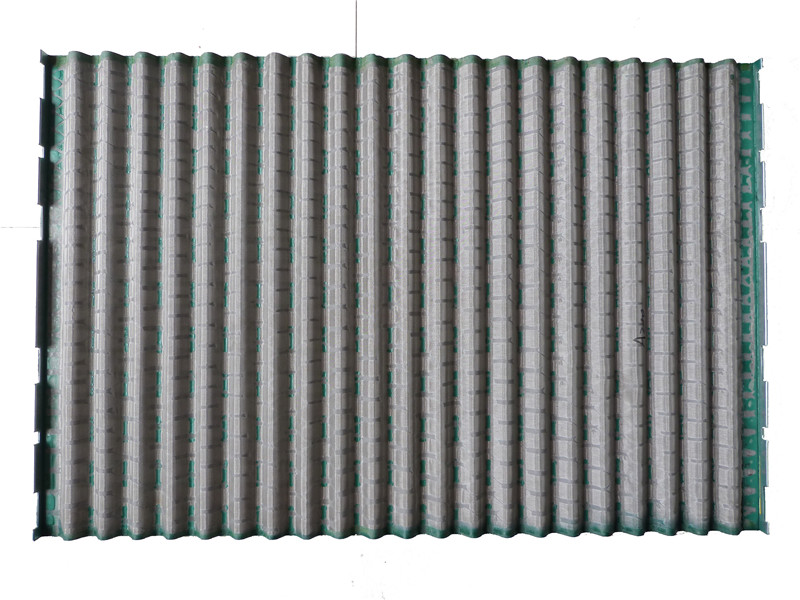

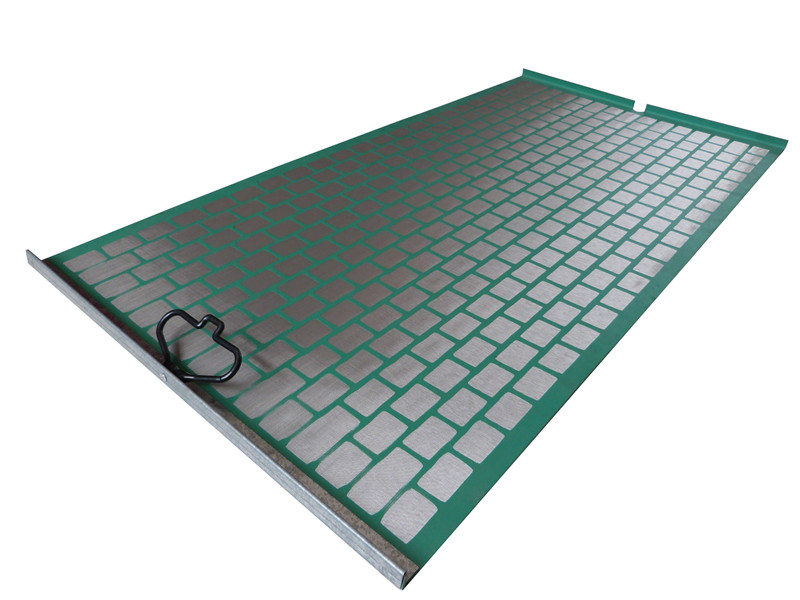

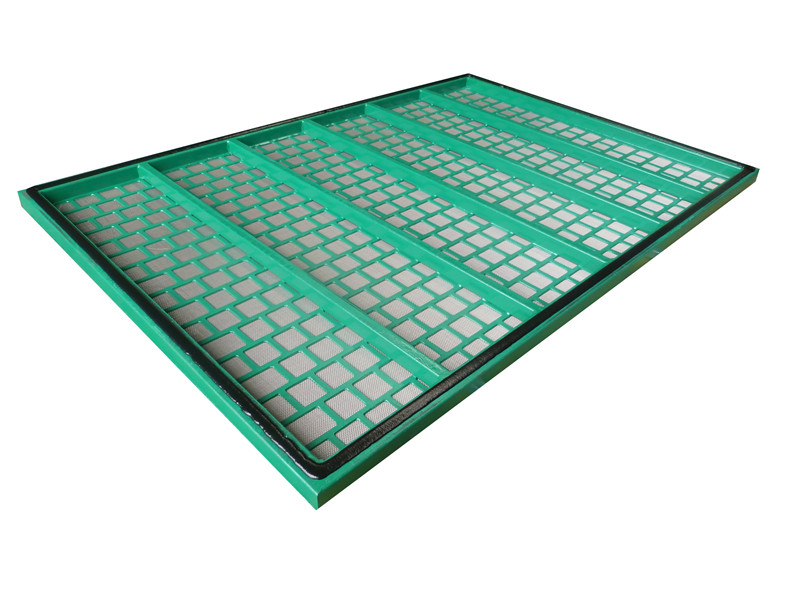

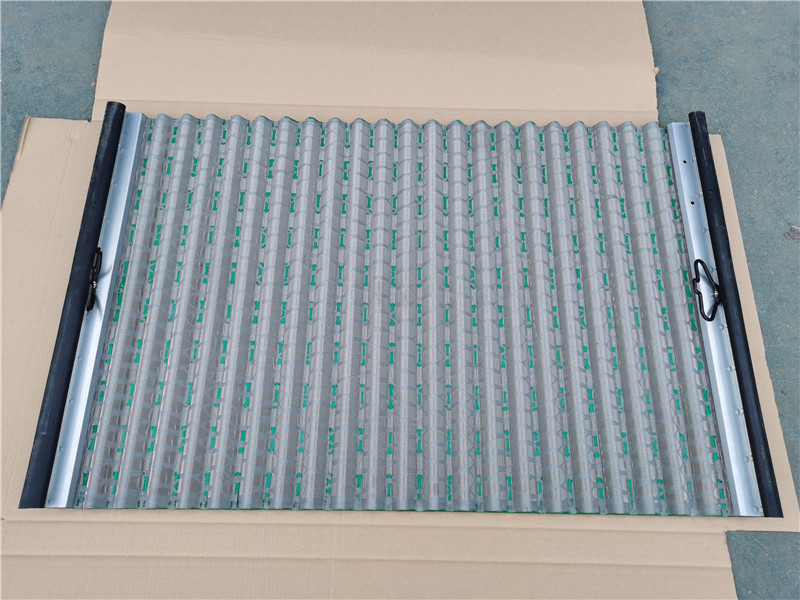

Derrock 500 PMD shaker screen replacement is manufactured for all Derrock 500 series shale shakers. Innovative tension fingers and two quick-lock 1/2 turn tension bolts on each screen panel make the installation faster, easier and more reliable. The bottom layer with low mesh counts is waved by coarse wires, then tightly bonded to the backing plate. It offers longer service life and maximizes the separation efficiency.

Adaptable Shale Shaker Model

KET-PMD 500 shaker screens are used as the substitute screen for

Derrock FLC (Flo-Line Cleaner) 503 shaker.

Derrock FLC (Flo-Line Cleaner) 504 shaker.

Derrock FLC (Flo-Line Cleaner) 503 drying shaker.

Derrock FLC (Flo-Line Cleaner) 504 drying shaker.

Derrock FLC (Flo-Line Cleaner) 513 shaker.

Derrock FLC (Flo-Line Cleaner) 514 shaker.

Derrock FLC (Flo-Line Cleaner) 513 VE (Vapor Extraction).

Derrock FLC (Flo-Line Cleaner) 514 VE (Vapor Extraction).

Competitive Advantage

Resistant to corrosion, high temperature and collision.

Quick-lock tension system, excellent trapping (dreg) effect.

56% more screen surface area than flat screens.

Maximize the solids removal capabilities.

Increase shaker capacity and reduce mud loss.

API RP 13C (ISO 13501) compliant.

Adequate inventory in the shortest time to meet customers’ demand.

Warranty Period: 1 year.

Working Life: 400–450 hours.

Performance Parameter

| Screen Designation | Mesh Type | API RP 13C Designation | Conductance Number | D100 Separation (microns) | Layer No. | Non-Blank Area (sq.ft) |

|---|---|---|---|---|---|---|

| KET-PMD 500-A325 | DF | API 325 | 0.39 | 44 | 2/3 | 7.09 |

| KET-PMD 500-A230 | DF | API 230 | 0.71 | 68 | 2/3 | 7.09 |

| KET-PMD 500-A200 | DX | API 200 | 1.32 | 73 | 2/3 | 7.09 |

| KET-PMD 500-A170 | DX | API 170 | 1.34 | 83 | 2/3 | 7.09 |

| KET-PMD 500-A140 | DX | API 140 | 1.89 | 101 | 2/3 | 7.09 |

| KET-PMD 500-A120 | DX | API 120 | 1.89 | 134 | 2/3 | 7.09 |

| KET-PMD 500-A100 | DX | API 100 | 2.66 | 164 | 2/3 | 7.09 |

| KET-PMD 500-A80 | DX | API 80 | 2.76 | 193 | 2/3 | 7.09 |

| KET-PMD 500-A70 | DX | API 70 | 3.33 | 203 | 2/3 | 7.09 |

| KET-PMD 500-A50 | DX | API 50 | 5.17 | 285 | 2/3 | 7.09 |

| KET-PMD 500-A40 | DX | API 40 | 8.64 | 439 | 2/3 | 7.09 |

| KET-PMD 500-A35 | DX | API 35 | 9.69 | 538 | 2/3 | 7.09 |

| KET-PMD 500-A20 | DF | API 20 | 10.88 | 809 | 2/3 | 7.09 |

| * D100: Particles this size and larger will normally be discarded.* API: Corresponding API sieve equivalent as per API RP 13C.* Conductance No.: This represents the ease with which a liquid can flow through the screen. Larger values represent higher volume handing. | ||||||

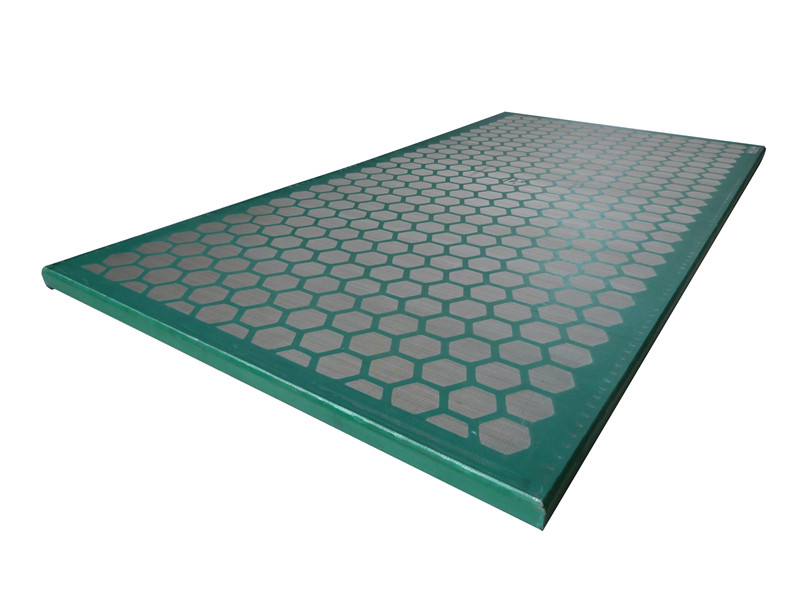

Product detail pictures:

Related Product Guide:

Our corporation puts emphasis about the administration, the introduction of talented staff, plus the construction of team building, attempting hard to improve the quality and liability consciousness of team members. Our organization successfully attained IS9001 Certification and European CE Certification of OEM Supply Used Derrock Shale Shaker Screen - Replacement Screen for Derrock 500 PMD – KANGERTONG, The product will supply to all over the world, such as: Bulgaria, Angola, Nepal, We believe with our consistently excellent service you can get the best performance and cost least goods from us for a long term . We commit to provide better services and create more value to all our customers. Hope we can create a better future together.

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.