OEM/ODM Supplier Derrock Shale Shaker - Replacement Screen for FLC 2000 48-30 – KANGERTONG

OEM/ODM Supplier Derrock Shale Shaker - Replacement Screen for FLC 2000 48-30 – KANGERTONG Detail:

Description

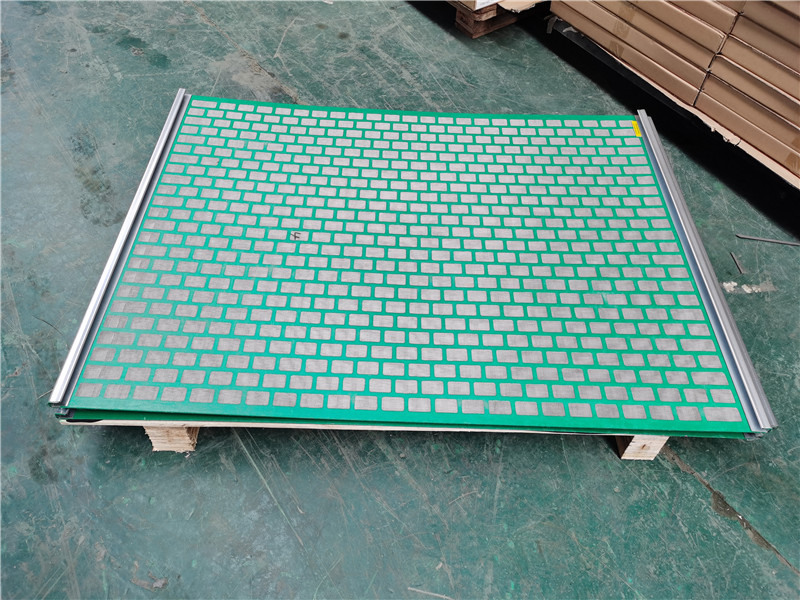

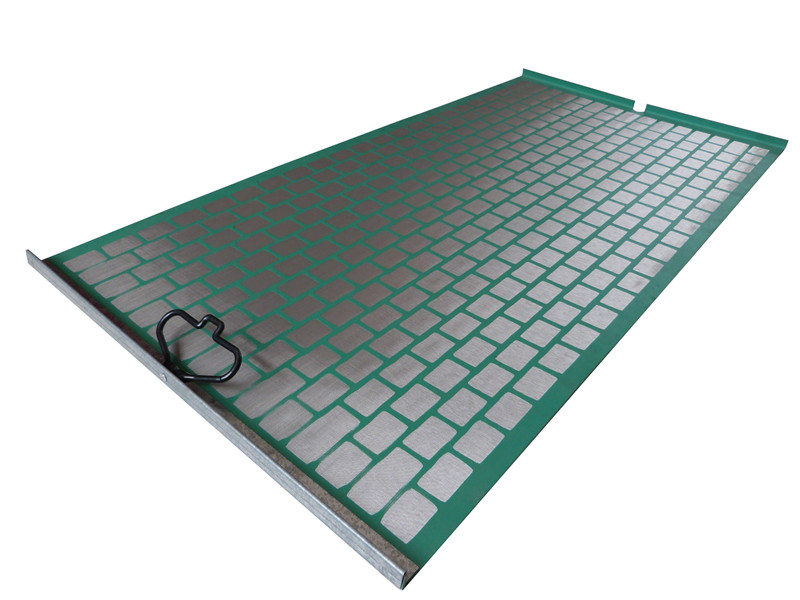

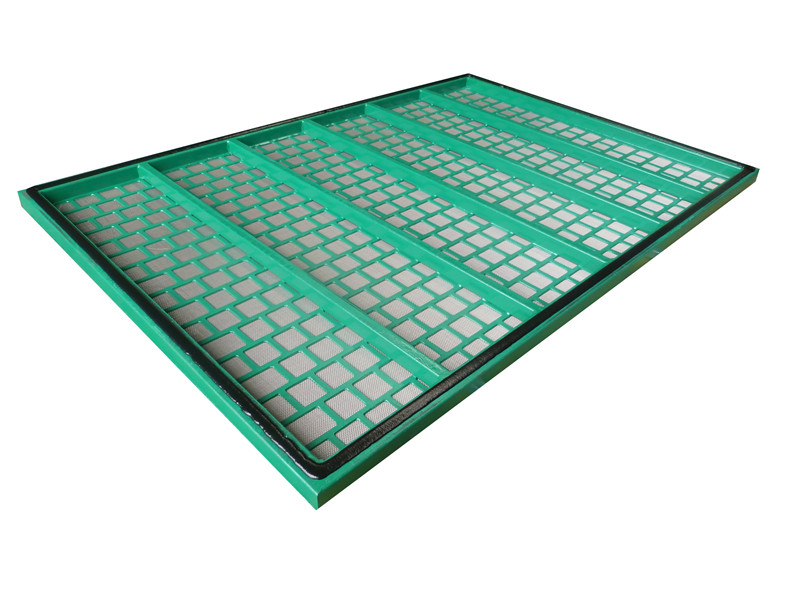

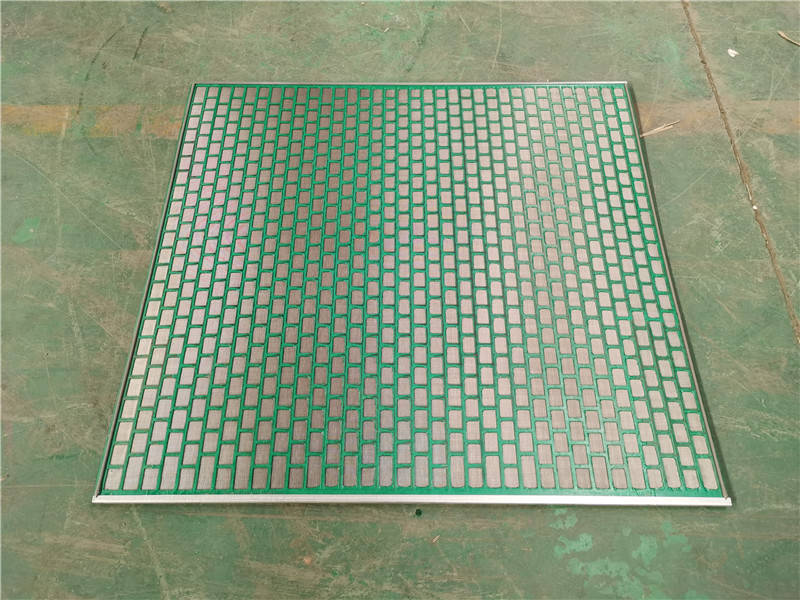

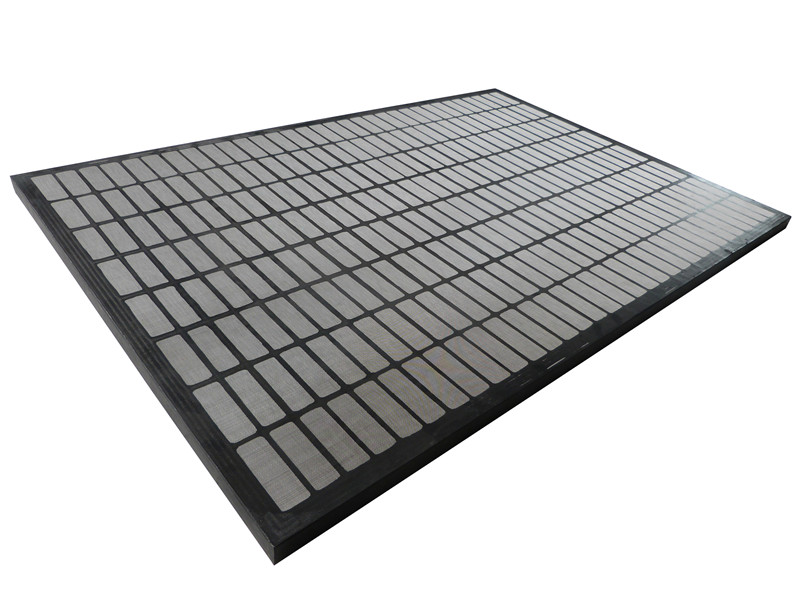

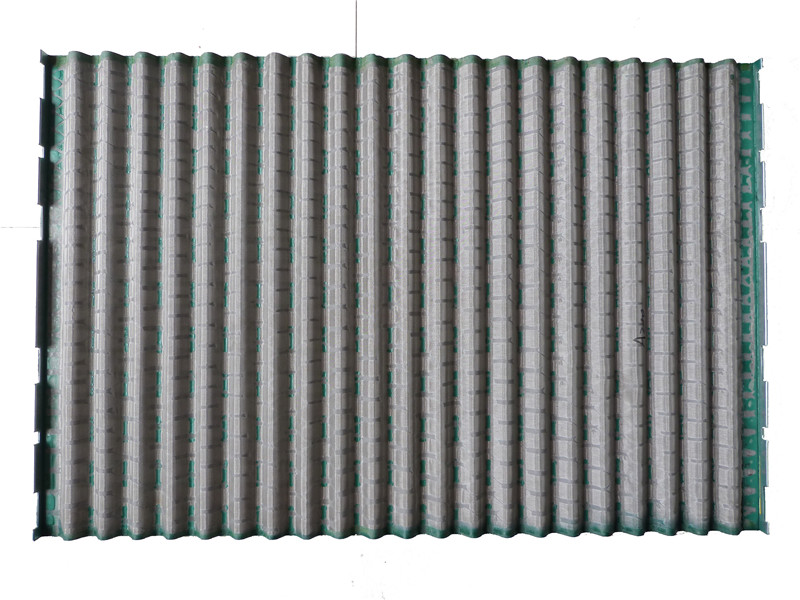

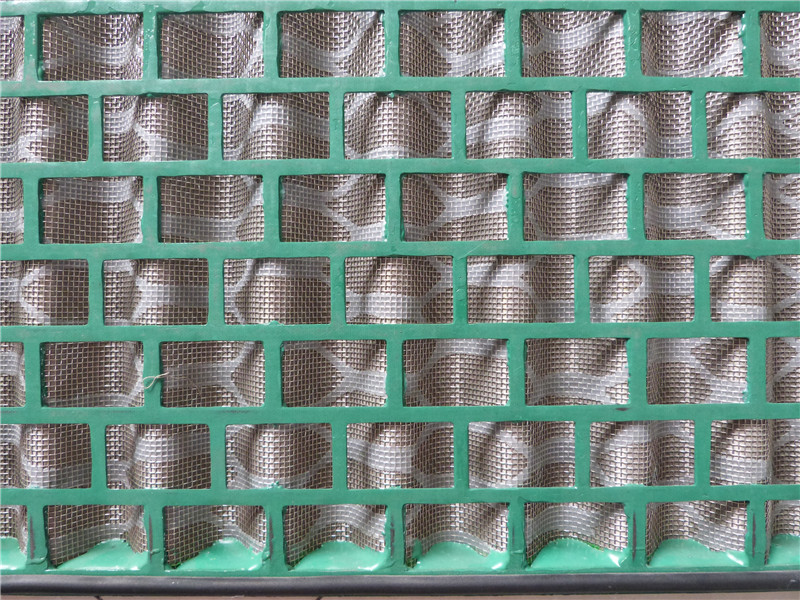

KET- 2000 shale shaker screen is manufactured based on the innovated design of Derrock Corporation. This type of shaker screen is constructed of multiple layers of stainless steel wire mesh cloth with different densities. Arrange these layers reasonably and exactly, the finished shale shaker screen with revolutionary three-dimensional corrugated screens structure. screens offer 125% to 150% usable areas of traditional flat multi-layered screens. And the fluid capacity also has been increased.

Adaptable Shale Shaker Model

KET- 2000 shaker screens are used as the substitute screen for

Derrock FLC (Flo-Line Cleaner) 2000 3-panel shaker.

Derrock FLC (Flo-Line Cleaner) 2000 4-panel shaker.

Derrock 48-30 shale shaker.

Derrock FLC (Flo-Line Cleaner) 2000 series mud cleaners.

Derrock FLC Plus, FLC with AWD, HI-G dryer.

Competitive Advantage

API RP 13C (ISO 13501) compliant.

Resistant to corrosion, high temperature and collision.

Larger area and higher conductance.

Increase shaker capacity and reduce mud loss.

Scientific & reasonable cost control system for competitive price.

Higher flow rates without sacrificing cut point integrity.

Adequate inventory in the shortest time to meet customers’ demand.

Warranty Period: 1 year.

Working Life: 400–450 hours.

Performance Parameter

| Screen Designation | Mesh Type | API RP 13C Designation | Conductance Number | D100 Separation (microns) | Layer No. | Non-Blank Area (sq.ft) |

|---|---|---|---|---|---|---|

| KET- 2000-A325 | DF | API 325 | 0.39 | 44 | 2/3 | 8.3 |

| KET- 2000-A270 | DF | API 270 | 0.67 | 57 | 2/3 | 8.3 |

| KET- 2000-A230 | DF | API 230 | 0.71 | 68 | 2/3 | 8.3 |

| KET- 2000-A200 | DX | API 200 | 1.32 | 73 | 2/3 | 8.3 |

| KET- 2000-A170 | DX | API 170 | 1.34 | 83 | 2/3 | 8.3 |

| KET- 2000-A140 | DX | API 140 | 1.89 | 101 | 2/3 | 8.3 |

| KET- 2000-A120 | DX | API 120 | 1.89 | 134 | 2/3 | 8.3 |

| KET- 2000-A100 | DX | API 100 | 2.66 | 164 | 2/3 | 8.3 |

| KET- 2000-A80 | DX | API 80 | 2.76 | 193 | 2/3 | 8.3 |

| KET- 2000-A70 | DX | API 70 | 3.33 | 203 | 2/3 | 8.3 |

| KET- 2000-A60 | DX | API 60 | 4.1. | 268 | 2/3 | 8.3 |

| KET- 2000-A50 | DX | API 50 | 5.17 | 285 | 2/3 | 8.3 |

| KET- 2000-A40 | DX | API 40 | 8.64 | 439 | 2/3 | 8.3 |

| KET- 2000-A35 | DX | API 35 | 9.69 | 538 | 2/3 | 8.3 |

| KET- 2000-A20 | DF | API 20 | 10.88 | 809 | 2/3 | 8.3 |

| * D100: Particles this size and larger will normally be discarded.* API: Corresponding API sieve equivalent as per API RP 13C.* Conductance No.: This represents the ease with which a liquid can flow through the screen. Larger values represent higher volume handing. | ||||||

Product detail pictures:

Related Product Guide:

We not only will try our best to offer excellent services to every customer, but also are ready to receive any suggestion offered by our customers for OEM/ODM Supplier Derrock Shale Shaker - Replacement Screen for FLC 2000 48-30 – KANGERTONG, The product will supply to all over the world, such as: Ethiopia, Portland, Austria, Look forward to the future, we will focus more on the brand building and promotion . And in the process of our brand global strategic layout we welcome more and more partners join us, work together with us based on mutual benefit. Let's develop market by fully utilizing our comprehensive advantages and strive for building.

Hope that the company could stick to the enterprise spirit of Quality, Efficiency, Innovation and Integrity, it will be better and better in the future.