Chinese wholesale Hi-G Cutting Dryer Shaker - Replacement Screen for BEM-3 PWP – KANGERTONG

Chinese wholesale Hi-G Cutting Dryer Shaker - Replacement Screen for BEM-3 PWP – KANGERTONG Detail:

DESCRIPTION

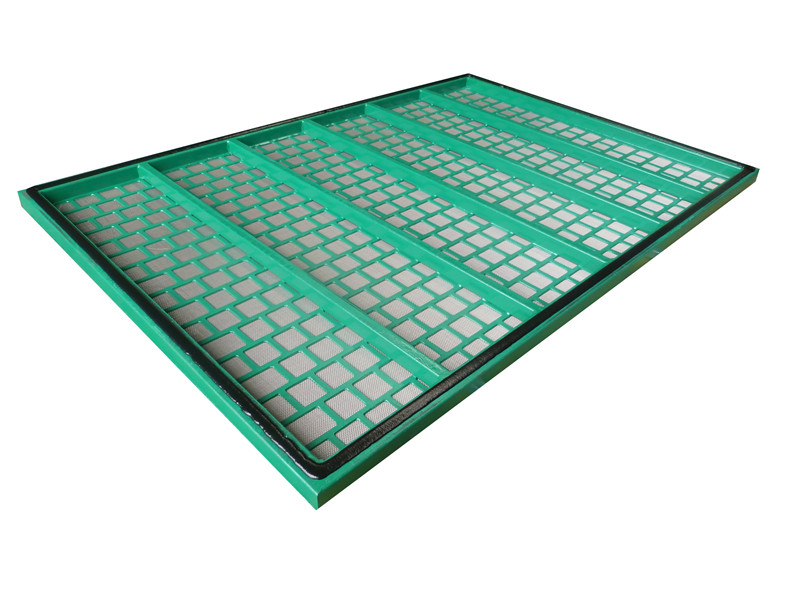

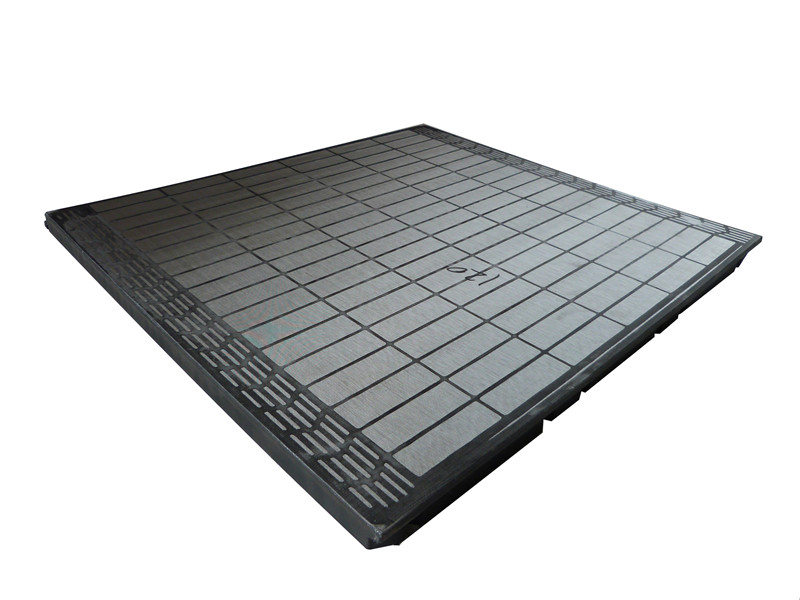

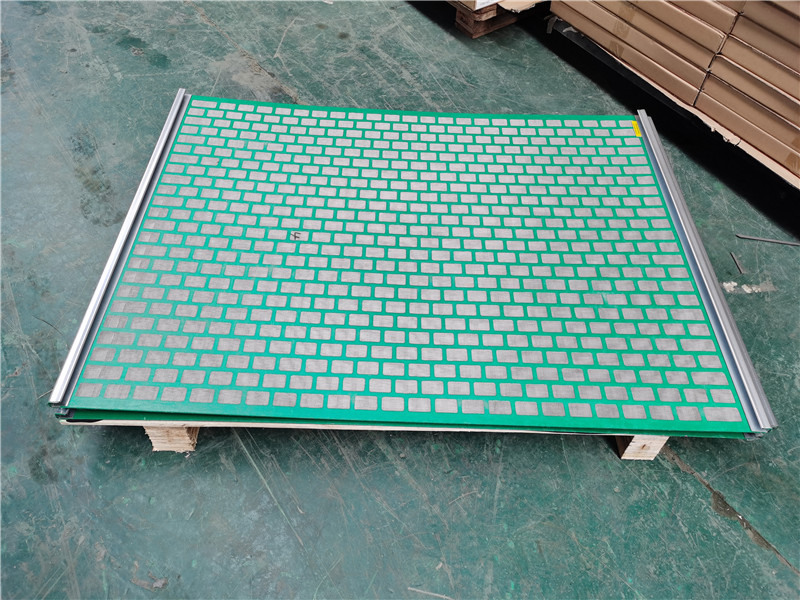

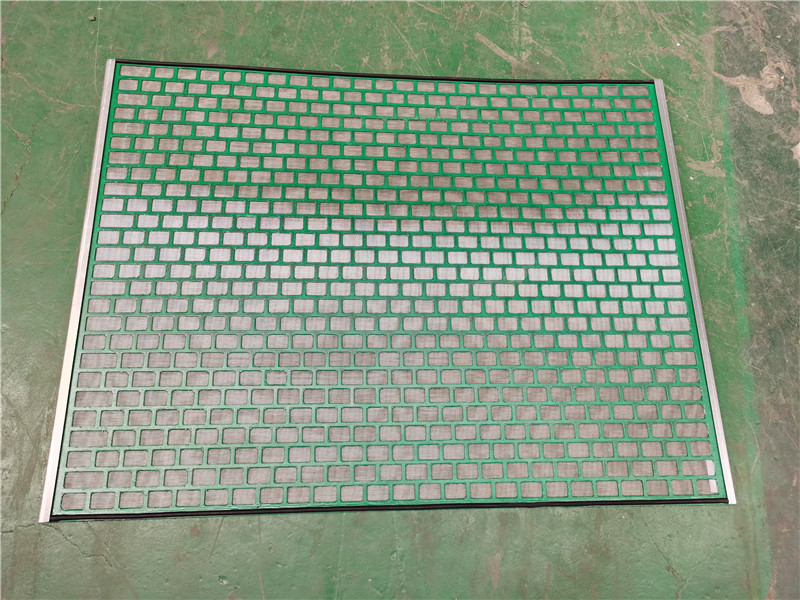

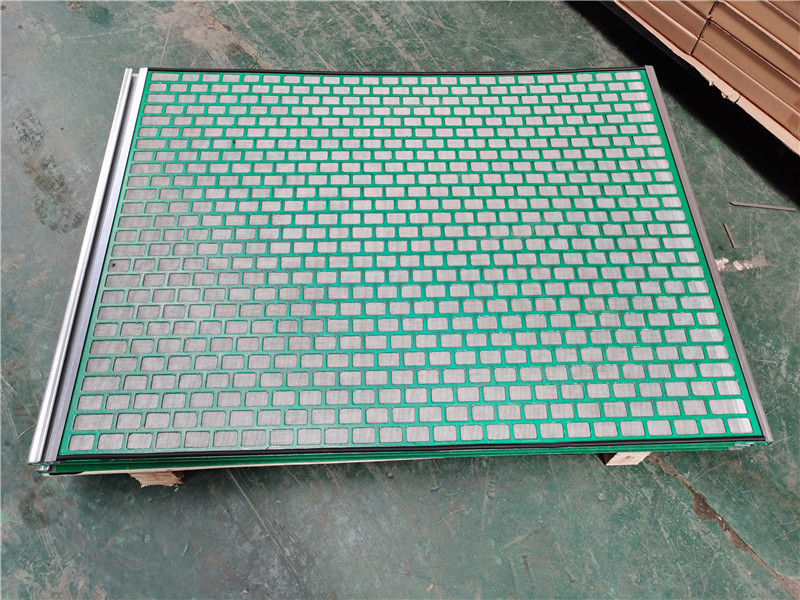

KET-BEM-3 shale shaker screens, also famous known as Swaco BEM-3 screens, are compatible with Swaco (Flo-Line Cleaner) BEM series shale shakers. It is a hook strip flat type shaker screen, which is constructed of multiple stainless steel 304 or 316 wire mesh cloth layers. And then bonded to a rectangular or hexagonal perforated metal plate for added support and facilitation of repair.

Adaptable Shale Shaker Model

KET-BEM-3 shaker screens are used as the substitute screen for

● Swaco BEM-3 (Flo-Line Cleaner) 3-panel shaker.

● Swaco BEM-3 (Flo-Line Cleaner) 4-panel shaker.

● Swaco BEM-3M shale shaker.

● Swaco BEM-3 series mud cleaners.

● Swaco BEM-3 Plus, FLC with AWD, HI-G dryer.

Competitive Advantage

● Manufactured according to the API RP 13C (ISO 13501).

● Top quality stainless steel wire mesh for longevity.

● Increase shaker capacity and reduce mud loss.

● Scientific & reasonable cost control system for competitive price.

● Higher flow rates without sacrificing cut point integrity.

● Adequate inventory in the shortest time to meet customers’ demand.

● Warranty Period: 1 year.

● Working Life: 400-450 hours.

Performance Parameter

|

Screen Designation |

Mesh Type |

API RP 13C Designation |

Conductance Number |

D100 Separation (microns) |

Layer No. |

Non-Blank Area (sq.ft) |

|

KET-BEM-3-A325 |

DF |

API 325 |

0.29 |

44 |

2/3 |

6.2 |

|

KET-BEM-3-A270 |

DF |

API 270 |

0.31 |

57 |

2/3 |

6.2 |

|

KET-BEM-3-A230 |

DF |

API 230 |

0.59 |

68 |

2/3 |

6.2 |

|

KET-BEM-3-A200 |

DX |

API 200 |

0.73 |

73 |

2/3 |

6.2 |

|

KET-BEM-3-A170 |

DX |

API 170 |

0.85 |

83 |

2/3 |

6.2 |

|

KET-BEM-3-A140 |

DX |

API 140 |

1.43 |

101 |

2/3 |

6.2 |

|

KET-BEM-3-A120 |

DX |

API 120 |

1.46 |

134 |

2/3 |

6.2 |

|

KET-BEM-3-A100 |

DX |

API 100 |

1.8 |

164 |

2/3 |

6.2 |

|

KET-BEM-3-A80 |

DX |

API 80 |

2.48 |

193 |

2/3 |

6.2 |

|

KET-BEM-3-A70 |

DX |

API 70 |

2.67 |

203 |

2/3 |

6.2 |

|

KET-BEM-3-A60 |

DX |

API 60 |

3.56 |

268 |

2/3 |

6.2 |

|

KET-BEM-3-A50 |

DX |

API 50 |

4.19 |

285 |

2/3 |

6.2 |

|

KET-BEM-3-A40 |

DX |

API 40 |

6.77 |

439 |

2/3 |

6.2 |

|

KET-BEM-3-A35 |

DX |

API 35 |

7.24 |

538 |

2/3 |

6.2 |

|

KET-BEM-3-A20 |

DF |

API 20 |

16.25 |

809 |

2/3 |

6.2 |

| * D100: Particles this size and larger will normally be discarded.* API: Corresponding API sieve equivalent as per API RP 13C.

* Conductance No.: This represents the ease with which a liquid can flow through the screen. Larger values represent higher volume handing. |

||||||

Product detail pictures:

Related Product Guide:

Persisting in High top quality, Prompt Delivery, Aggressive Price, now we have established long-term cooperation with customers from the two overseas and domestically and get new and aged clients' large comments for Chinese wholesale Hi-G Cutting Dryer Shaker - Replacement Screen for BEM-3 PWP – KANGERTONG, The product will supply to all over the world, such as: Israel, US, Oman, We have more than 10 years exported experience and our products have expored more than 30 countries around the word . We always hold the service tenet Client first,Quality first in our mind,and are strict with product quality. Welcome your visiting!

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!