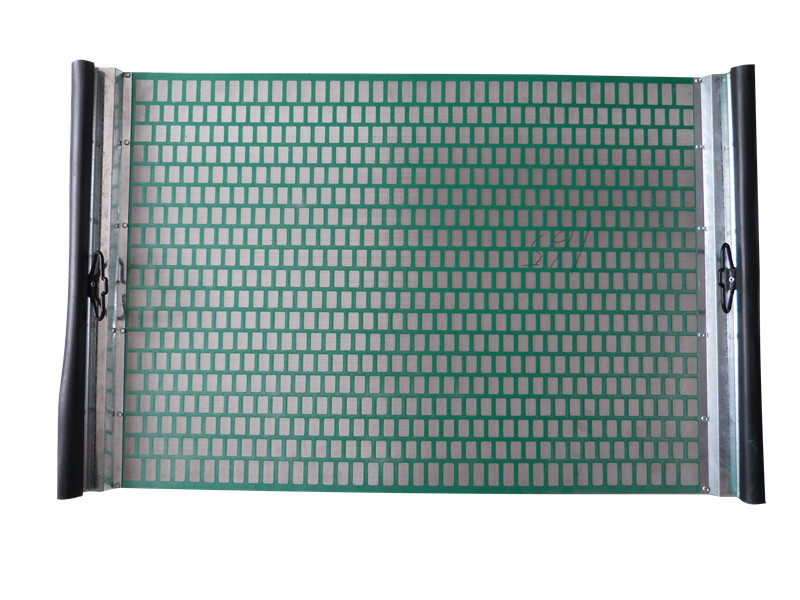

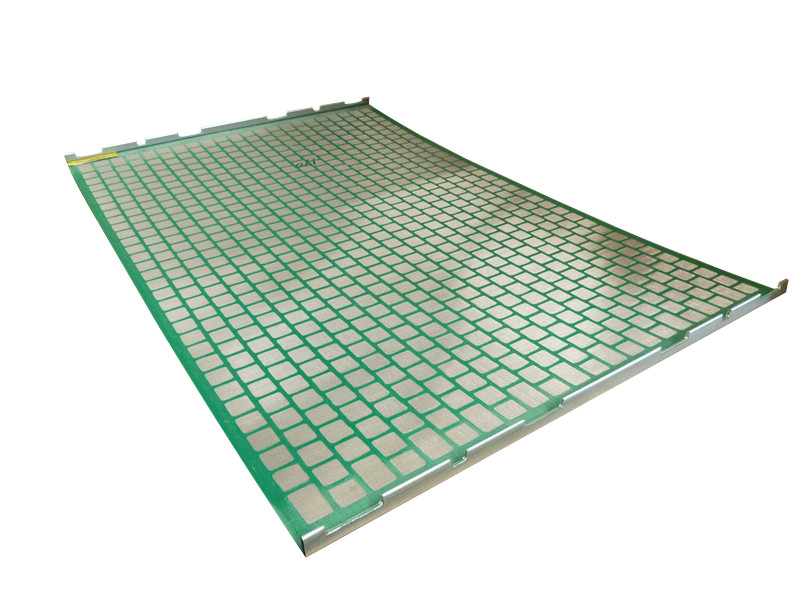

Replacement Screen for Derrock 626

DESCRIPTION

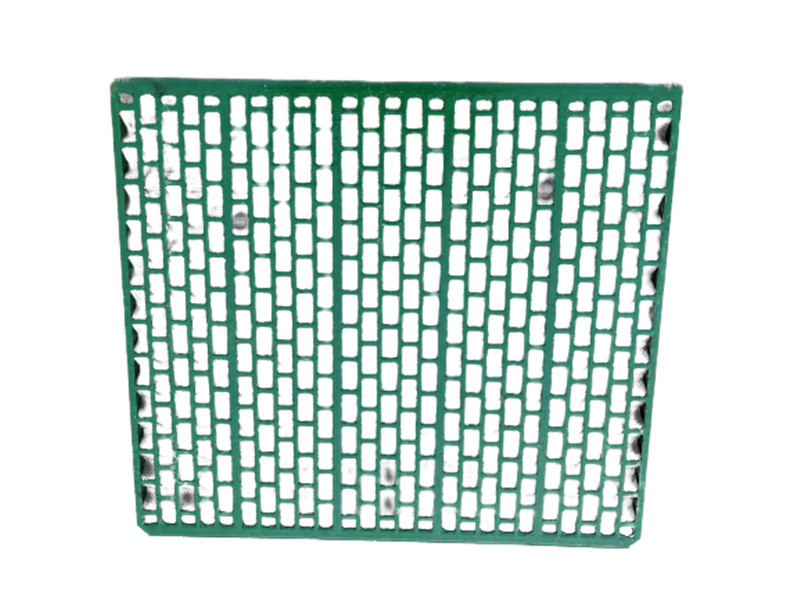

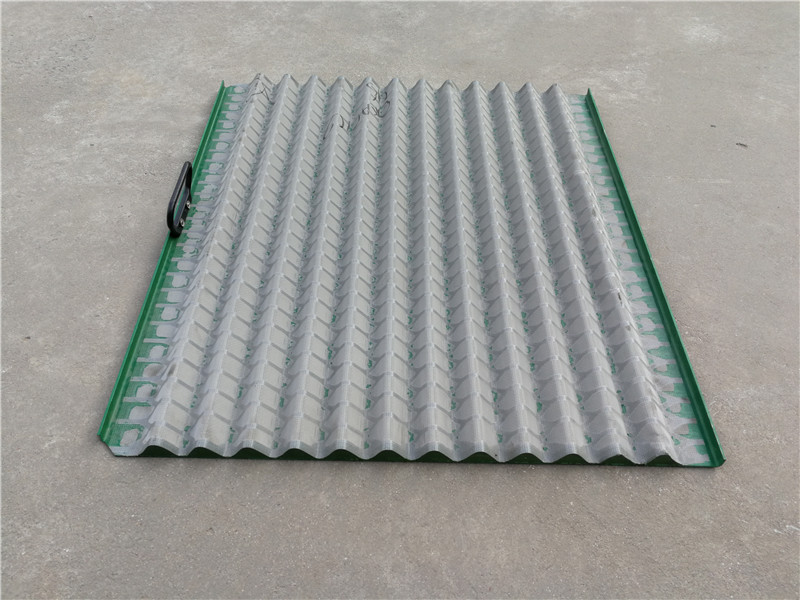

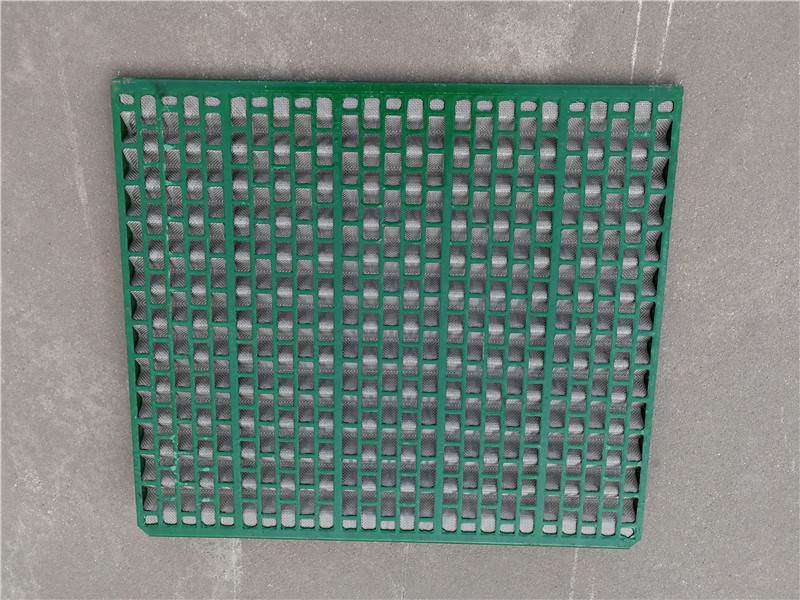

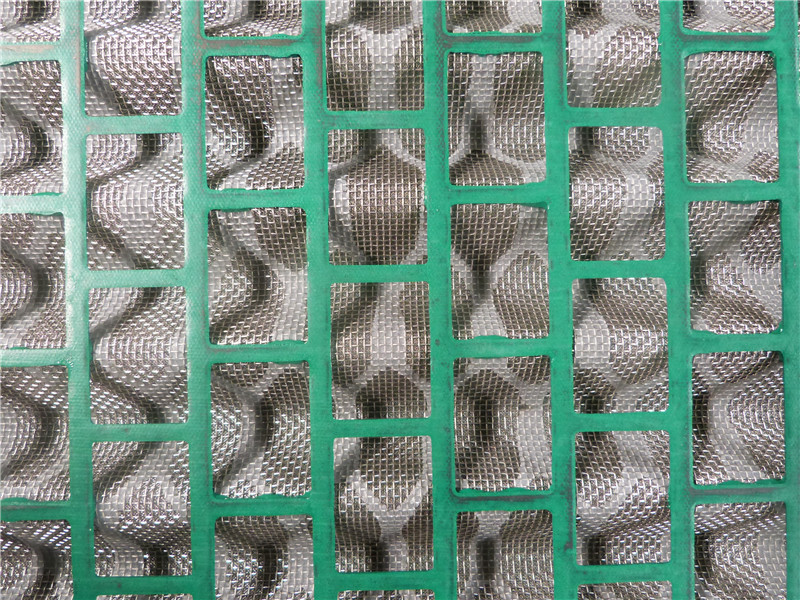

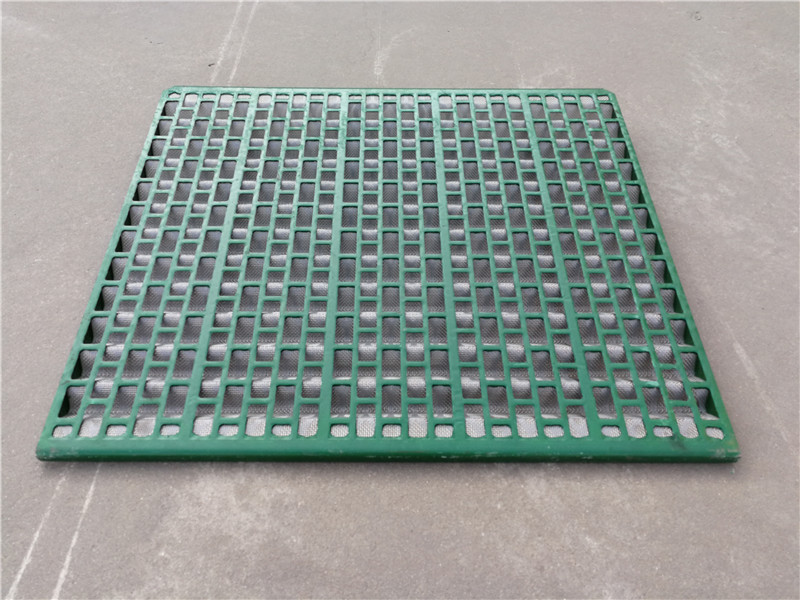

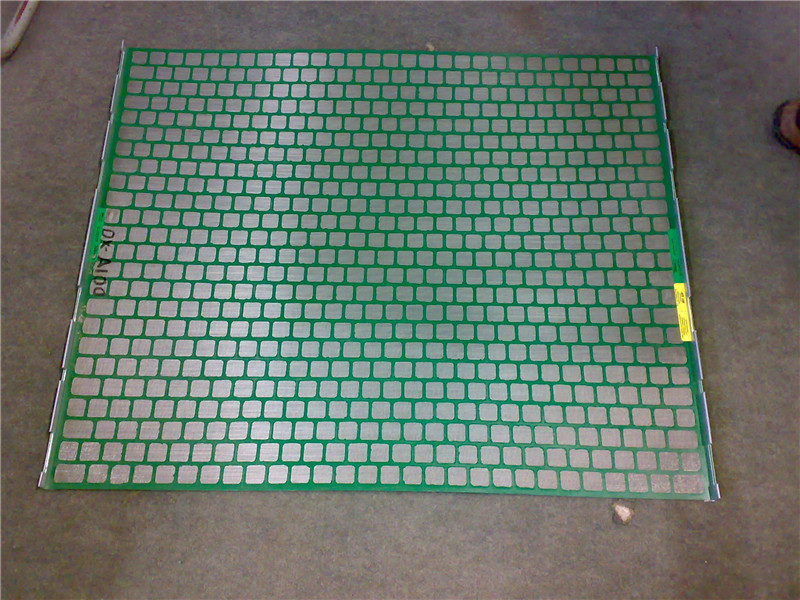

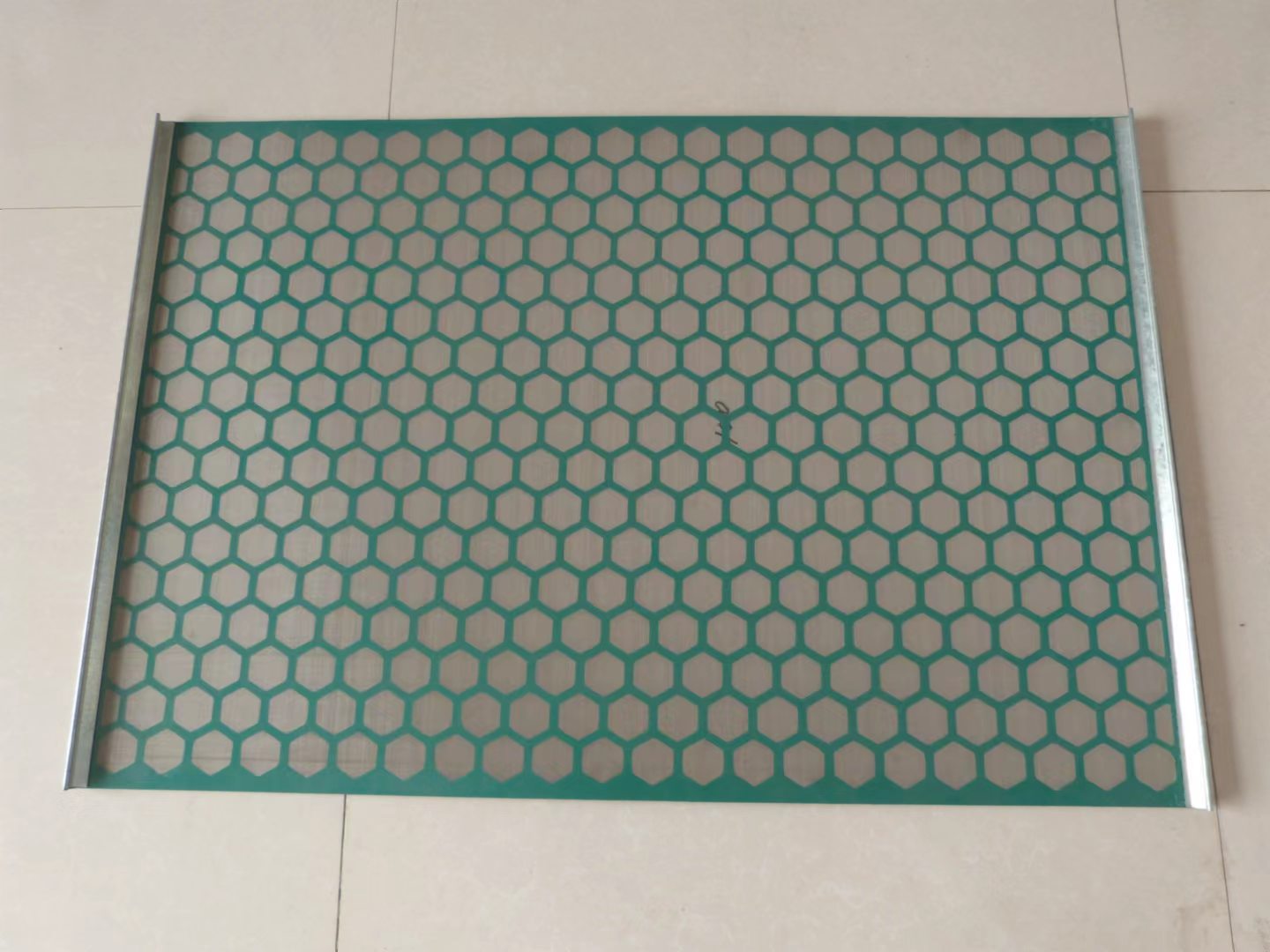

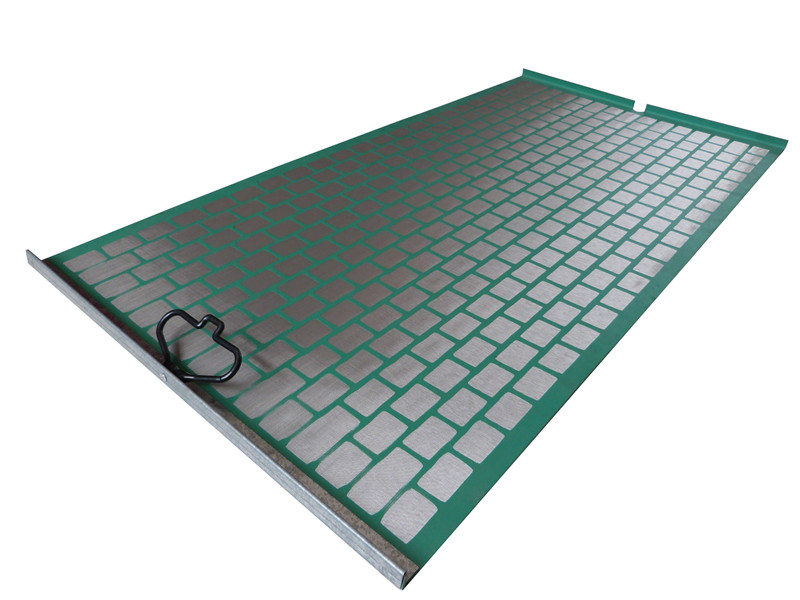

KET-PMD DP 600 shaker screen with dimension of 626 × 710 mm which is smaller than other screen panels, it is the replacement screen for Derrock Dual pool 600 series shale shakers. There are 6 or 8 panels needed for each DP 600 shaker. Innovative actuated screen compression system drives the center of the screen panel downward and firmly sealing the screen panel to the screen frame. The mud recovery is greatly improved.

Adaptable Shale Shaker Model

KET-PMD DP 600 shaker screens are used to as the substitute screen for:

Derrock DP (Dual Pool) 626 shaker.

Derrock DP (Dual Pool) 616 shaker.

Derrock DP (Dual Pool) 628 shaker.

Derrock DP (Dual Pool) 618 shaker.

Derrock DP (Dual Pool) 626 VE (Vapor Extraction).

Derrock DP (Dual Pool) 616 VE (Vapor Extraction).

Derrock DP (Dual Pool) 628 VE (Vapor Extraction).

Derrock DP (Dual Pool) 618 VE (Vapor Extraction).

Competitive Advantage

Light-weight screen panels for fast, user-friendly screen changes.

Easy screen inspection, removal, and installation.

Maximize solids removal capabilities.

Increase shaker capacity and reduce mud loss.

API RP 13C (ISO 13501) compliant.

Adequate inventory in the shortest time to meet customers’ demand.

Warranty Period: 1 year.

Working Life: 400–450 hours.

Performance Parameter

|

Screen Designation |

Mesh Type |

API RP 13C Designation |

Conductance Number |

D100 Separation (microns) |

Layer No. |

Screen area (sq.ft) |

|

KET-PMD DP 600-A200 |

DX |

API 200 |

0.95 |

78 |

2/3 |

4.85 |

|

KET-PMD DP 600-A170 |

DX |

API 170 |

1.36 |

97 |

2/3 |

4.85 |

|

KET-PMD DP 600-A140 |

DX |

API 140 |

1.92 |

115 |

2/3 |

4.85 |

|

KET-PMD DP 600-A120 |

DX |

API 120 |

1.92 |

120 |

2/3 |

4.85 |

|

KET-PMD DP 600-A100 |

DX |

API 100 |

2.33 |

154 |

2/3 |

4.85 |

|

KET-PMD DP 600-A80 |

DX |

API 80 |

3.09 |

184 |

2/3 |

4.85 |

|

KET-PMD DP 600-A70 |

DX |

API 70 |

3.80 |

221 |

2/3 |

4.85 |

|

KET-PMD DP 600-A60 |

DX |

API 60 |

4.68 |

257 |

2/3 |

4.85 |

|

KET-PMD DP 600-A50 |

DX |

API 50 |

5.50 |

314 |

2/3 |

4.85 |

|

KET-PMD DP 600-A45 |

DX |

API 45 |

5.84 |

360 |

2/3 |

4.85 |

|

KET-PMD DP 600-A40 |

DX |

API 40 |

6.59 |

453 |

2/3 |

4.85 |

|

KET-PMD DP 600-A35 |

DX |

API 35 |

7.06 |

503 |

2/3 |

4.85 |

|

KET-PMD DP 600-A325 |

DF |

API 325 |

0.38 |

44 |

2/3 |

4.85 |

|

KET-PMD DP 600-A270 |

DF |

API 270 |

0.44 |

53 |

2/3 |

4.85 |

|

KET-PMD DP 600-A230 |

DF |

API 230 |

0.71 |

67 |

2/3 |

4.85 |

|

KET-PMD DP 600-A20 |

DF |

API 20 |

0.93 |

821 |

2/3 |

4.85 |

| * D100: Particles this size and larger will normally be discarded.* API: Corresponding API sieve equivalent as per API RP 13C.

* Conductance No.: This represents the ease with which a liquid can flow through the screen. Larger values represent higher volume handing. |

||||||