ODM Best Replacement Screen Manufacturers – Replacement Screen for DFE – KANGERTONG

ODM Best Replacement Screen Manufacturers – Replacement Screen for DFE – KANGERTONG Detail:

DESCRIPTION

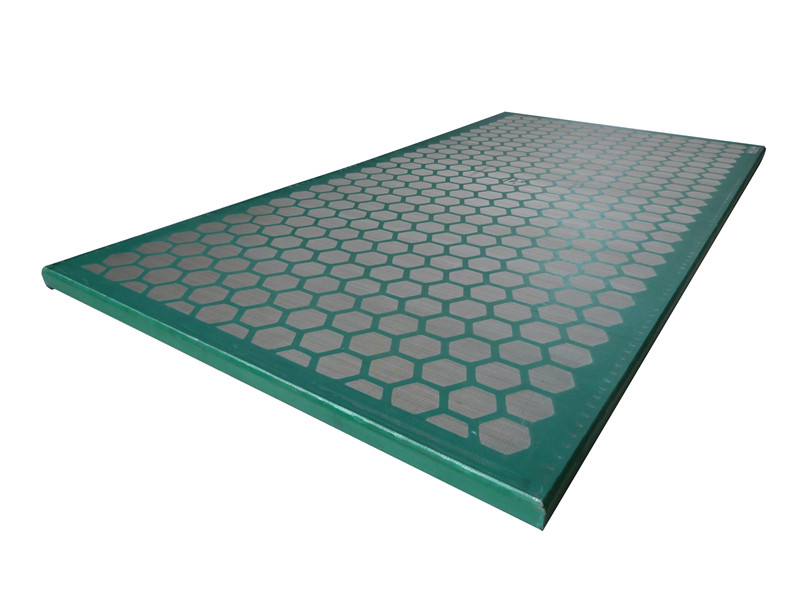

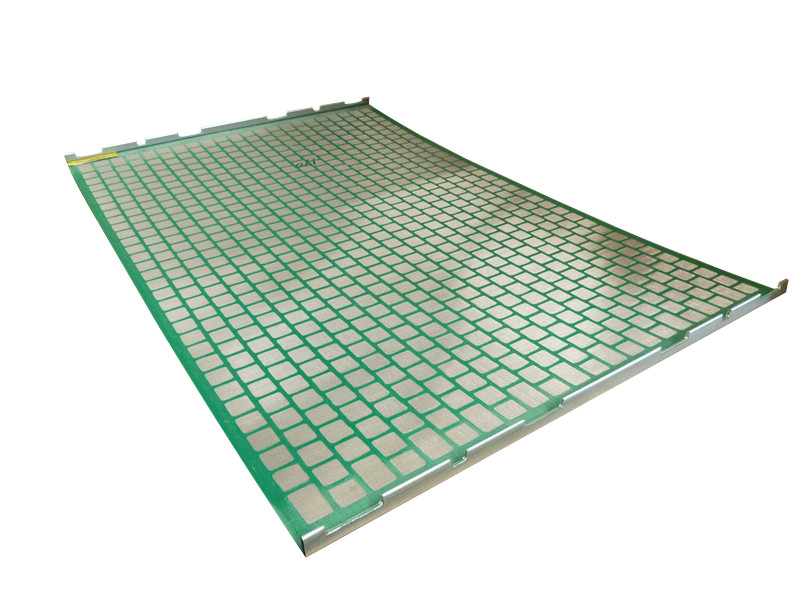

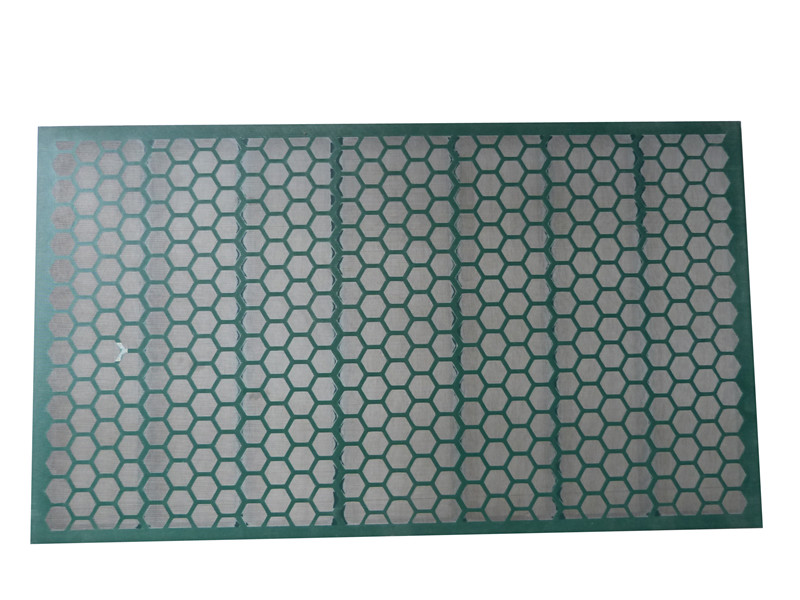

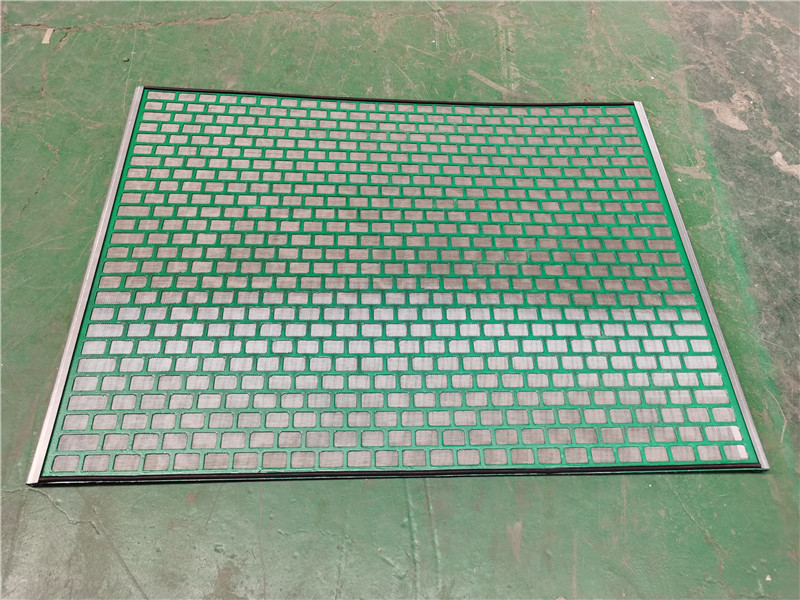

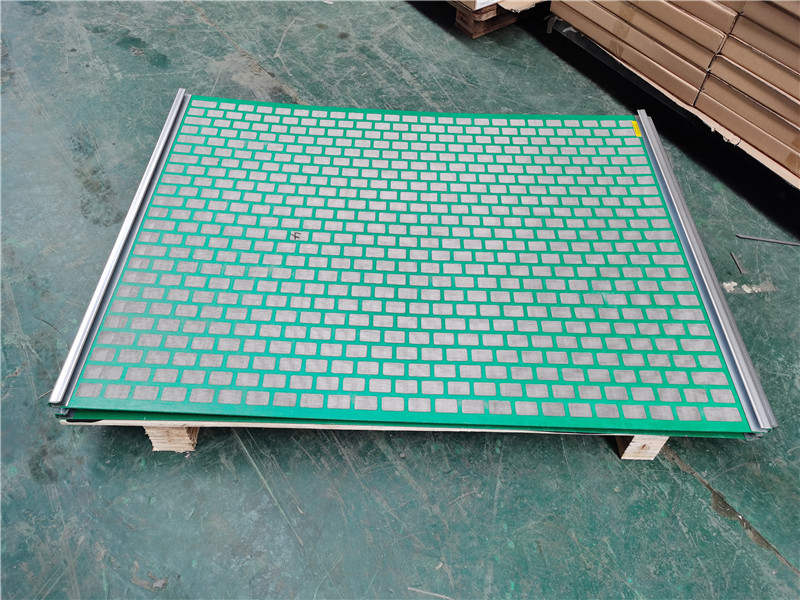

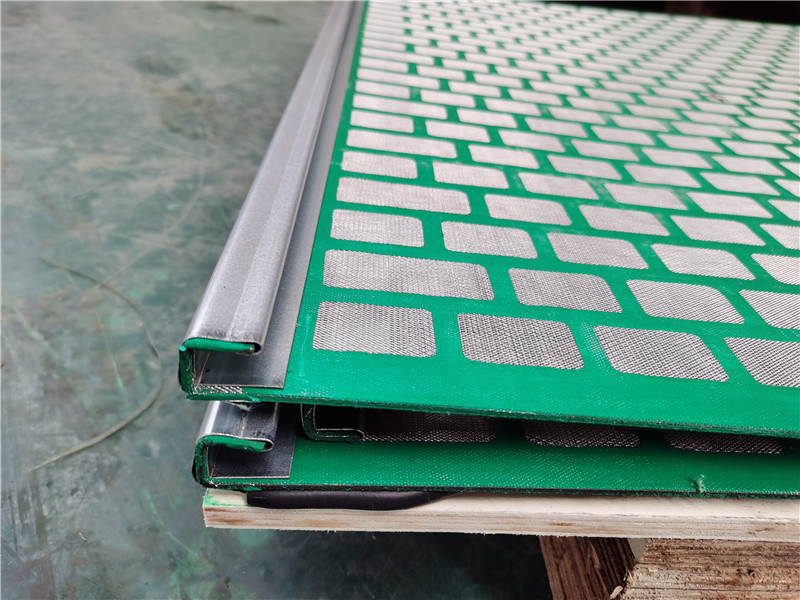

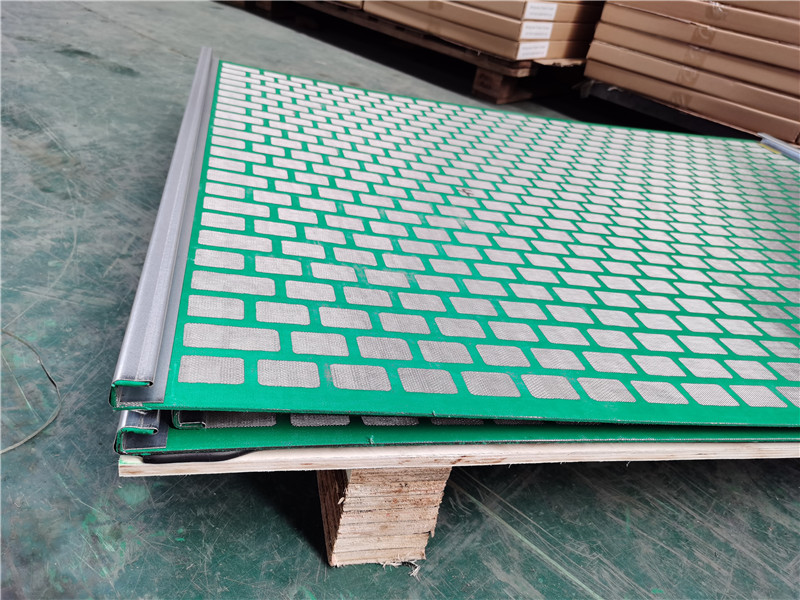

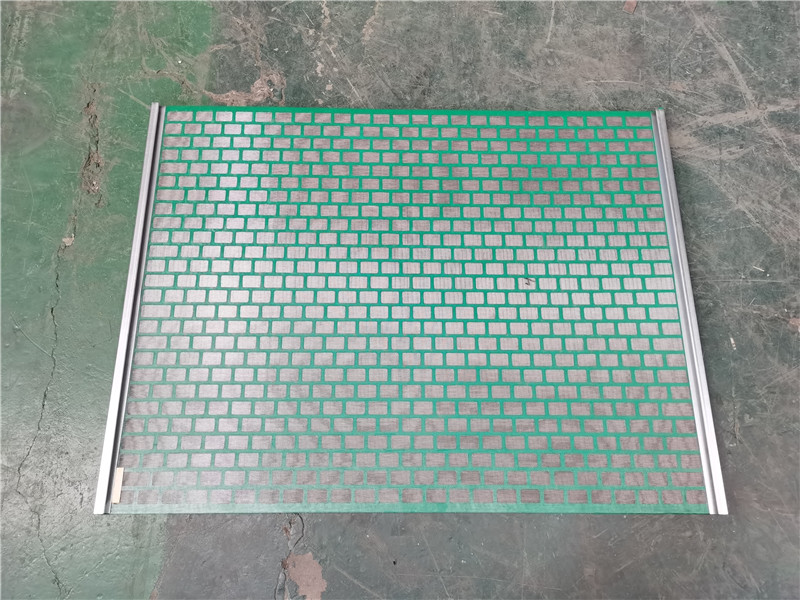

KET-DFE shale shaker screens, also famous known as DFE screens, are compatible with DFE series shale shakers. It is a hook strip flat type shaker screen, which is constructed of multiple stainless steel 304 or 316 wire mesh cloth layers. And then bonded to a rectangular or hexagonal perforated metal plate for added support and facilitation of repair.

Adaptable Shale Shaker Model

KET-DFE shaker screens are used as the substitute screen for

● DFE 3-panel shaker.

● DFE 4-panel shaker.

● DFE series mud cleaners.

● DFE Plus, FLC with AWD, HI-G dryer.

Competitive Advantage

● Manufactured according to the API RP 13C (ISO 13501).

● Top quality stainless steel wire mesh for longevity.

● Increase shaker capacity and reduce mud loss.

● Scientific & reasonable cost control system for competitive price.

● Higher flow rates without sacrificing cut point integrity.

● Adequate inventory in the shortest time to meet customers’ demand.

● Warranty Period: 1 year.

● Working Life: 400-450 hours.

Performance Parameter

|

Screen Designation |

Mesh Type |

API RP 13C Designation |

Conductance Number |

D100 Separation (microns) |

Layer No. |

Non-Blank Area (sq.ft) |

|

KET-DFE-A325 |

DF |

API 325 |

0.29 |

44 |

2/3 |

5.5 |

|

KET-DFE-A270 |

DF |

API 270 |

0.31 |

57 |

2/3 |

5.5 |

|

KET-DFE-A230 |

DF |

API 230 |

0.59 |

68 |

2/3 |

5.5 |

|

KET-DFE-A200 |

DX |

API 200 |

0.73 |

73 |

2/3 |

5.5 |

|

KET-DFE-A170 |

DX |

API 170 |

0.85 |

83 |

2/3 |

5.5 |

|

KET-DFE-A140 |

DX |

API 140 |

1.43 |

101 |

2/3 |

5.5 |

|

KET-DFE-A120 |

DX |

API 120 |

1.46 |

134 |

2/3 |

5.5 |

|

KET-DFE-A100 |

DX |

API 100 |

1.8 |

164 |

2/3 |

5.5 |

|

KET-DFE-A80 |

DX |

API 80 |

2.48 |

193 |

2/3 |

5.5 |

|

KET-DFE-A70 |

DX |

API 70 |

2.67 |

203 |

2/3 |

5.5 |

|

KET-DFE-A60 |

DX |

API 60 |

3.56 |

268 |

2/3 |

5.5 |

|

KET-DFE-A50 |

DX |

API 50 |

4.19 |

285 |

2/3 |

5.5 |

|

KET-DFE-A40 |

DX |

API 40 |

6.77 |

439 |

2/3 |

5.5 |

|

KET-DFE-A35 |

DX |

API 35 |

7.24 |

538 |

2/3 |

5.5 |

|

KET-DFE-A20 |

DF |

API 20 |

14.35 |

809 |

2/3 |

5.5 |

| * D100: Particles this size and larger will normally be discarded.* API: Corresponding API sieve equivalent as per API RP 13C.

* Conductance No.: This represents the ease with which a liquid can flow through the screen. Larger values represent higher volume handing. |

||||||

Product detail pictures:

Related Product Guide:

The corporate keeps towards the operation concept scientific administration, superior quality and performance primacy, client supreme for ODM Best Replacement Screen Manufacturers – Replacement Screen for DFE – KANGERTONG, The product will supply to all over the world, such as: Armenia, Moscow, Sevilla, Our faith is to be honest first, so we just supply high quality products to our customers. Really hope that we can be business partners. We believe that we can establish long time business relationship with each other. You can contact us freely for more information and pricelist of our products ! You will be Unique with our hair products !!

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.